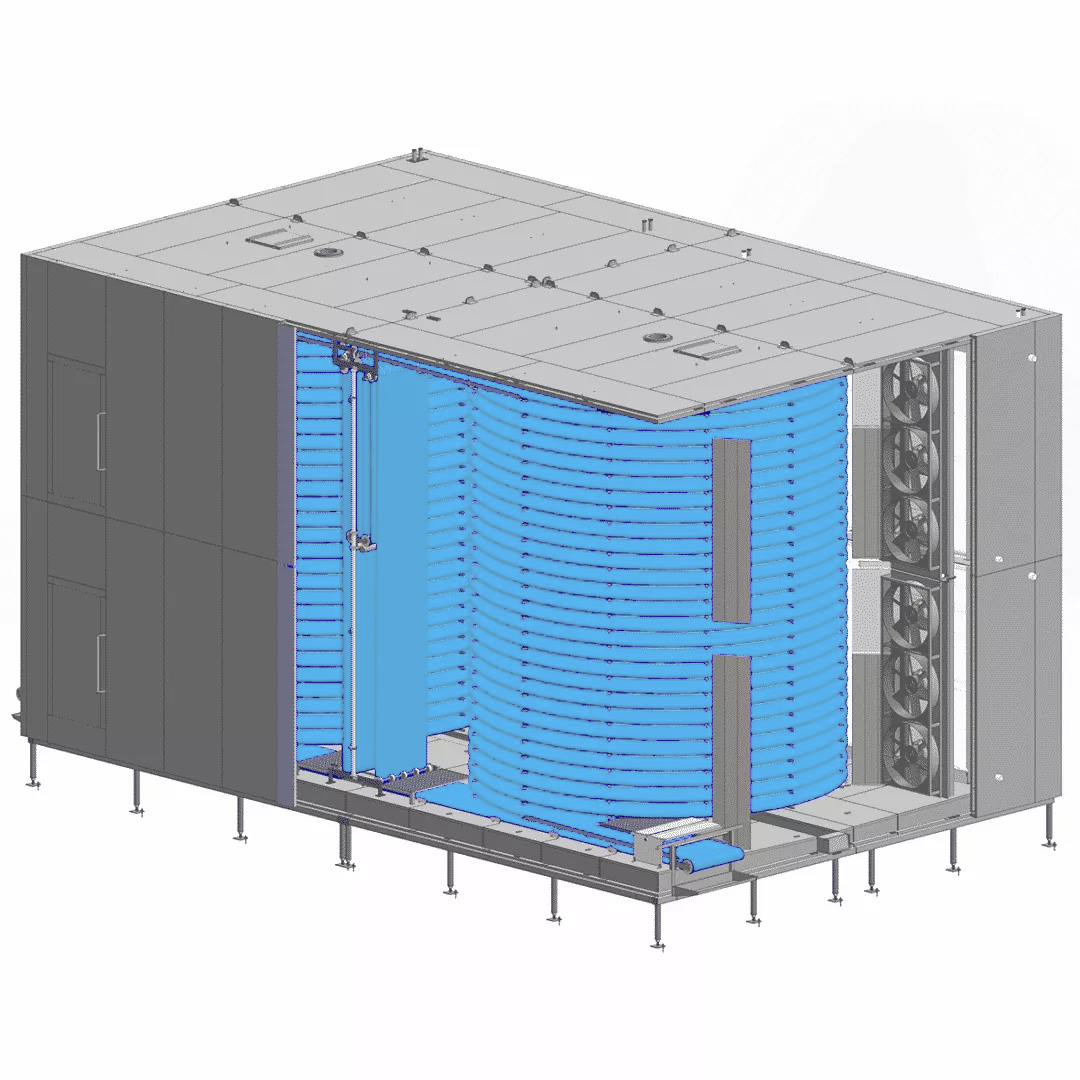

Twin Double Drum Spiral Freezer manufactured by Advanced Equipment Inc.

Advanced Twin Double Drum Spiral Freezer

- Saving energy consumption;

- Saving flour occupying;

- Retention time is much flexible; the adjusted range is larger.

Twin Double Drum Spiral Freezer manufactured by Advanced Equipment Inc.

Ideal solution for packed or large size products

WORKING PRINCIPLE

The Product is fed directly onto the freezer conveyor belt and transported into the freezing zone. A Conveyor belt on tier carriers travels up around a rotating drum that driven by a central capstan drive. The cold air is circulated continuously through product surfaces and evaporator coil by axial fans. Cold air will rapidly freeze the product during conveyor belt movement from in-feed to out-feed.

A unique built-in full Stainless-Steel construction, the Advanced Twin Double Drum Spiral Freezer has set new standards in spiral freezer design and ergonomics, allowing for operational efficiency, ultimate durability, low maintenance, easy cleaning and great flexibility.

Drum spiral freezer of hygiene design features a unique pattern of air circulation, ensures even and quick freezing without excessive airspeeds that might damage delicate products.

Each freezer can be customized to meet individual customer requirements.

KEY FEATURES

- Flat low tension belt design for ultimate life cycle

- Handling capacity from 500kg/hr to 6,000kg/hr

- Single or double drum, twin belt systems available as well

- Range of belt sizes and link heights available

- Multitude of belt in-feed/out-feed layout combinations

- Special frost tolerance designs for extended run times

- PLC touch screen control to optimize operation

- Range of automated Clean-in-Place (CIP) sanitizing systems

- Open profile and non-hollow design for frame members and parts, easy access everywhere.

- Stainless-steel construction and fixings for improved life and hygiene High identify plastics-All plastics are made from UHMW

- polyethylene(PE) & acetyl (POM), which are approved for food contact to ensure safety

- Various customized options available to meet specific application conditions

OPTIONAL ITEMS

- Sequential defrost systems

- Steam injection defrost systems

- Seam welded enclosure available

- Stainless support platform available

- Customized layouts and spiral rotations+

Ideal solution for packed or large size products

Products: Poultry, meat patties, raw shrimp, fish fillets, scallops, whole fish, packaged food in trays, ice cream cups, products requiring a long retention time.

APPLICATION

Drum spiral freezer is suitable for freezing and chilling food that requires medium to long retention times, especially suitable for large or packaged products, such as poultry, pizza, ready meals, potato products, fish & seafood, desserts, bakery products and ice-cream.

MAIN STRUCTURE TWIN DOUBLE SPIRAL FREEZER

1. Stainless-steel conveyor belt:

The conveyor belt is made of food grade stainless steel. The surface of the belt is flat and neat. There are baffle edges on both sides of the belt, which can prevent the products from dropping.

2. Insulation panels:

PUF sandwich panels, 150 mm thick with 42 kg/m3 density, laminated both sides by stainless-steel sheet.

3. Door:

Equipped with double seals and frame heating system

4. Inner structure:

The drum is designed in squirrel cage structure, and the components on which touching with conveyor belt are in arc shape. We inlaid the column bar of the drum with UHM-PE (ultra-high molecular weight polyethylene) materials, which have a good wear-resistance performance.

5. Driving device:

Speed reducer + Variable speed controller

6. Evaporator and fan:

Both the fins and tubes are made of aluminum alloy. The frame structure of the evaporator is made of food grade stainless steel. The air-box of the axial fan is made of food grade stainless steel, while the fan blades are made of aluminum alloy.

7. Belt tension device:

We adopt floating axle weight as a belt tension device. The tension degree of the conveyor belt can be adjusted.

8. Water slot (water plate) and drainage design:

The water slot will be installed on top of floor panels. It is made of food grade stainless steel. The water slot has a proper slope to facilitate water discharging and avoid defrosting water penetrating into the floor panels.

9. Inlet device and outlet device:

Both the inlet device and outlet device are made of food grade stainless steel.

10. Control panel:

We adopt Schneider or Siemens electrical components.

The best IQF freezer for quick freezing all kinds of fruit & vegetables and some seafood.

Adopts the two stage belting structure — firstly, quick-cooling stage. Secondly, the deep-freezing stage. Independently speed control system, and the speed of the two mesh-belts can be changed infinitely.

1. Quick-cooling stage — the food particles are to be quick cooled after entering into the blast room. The surface of the particles would have frozen and reach the temperature of 0 C. meanwhile, with the help of the striking chain, the particles would neither stick together nor sticking on the stainless steel mesh-belt.

2. Deep-freezing stage — the food is to be moved on a stainless steel mesh-belt, the foodstuff layer loosens with the increasing of the airflow. Some foodstuff particles become floating (this is the reason this equipment is not applicable to big bulk foodstuffs) when the air pressure reaches a certain scale, which brings interspace among the foodstuff particles, that is the way the Fluidized bed comes into being.

The floating particles freeze quickly and individually because they are blowing with strong cool air from all directions.

Spiral freezer Descriptions,

Evaporator, adopts the aluminum tube coated with aluminum plate, unique alternative fin space design, which helps to prolong the defrosting time.

High-pressure fan, to guarantee the foodstuff to stay floating and prevent the particles from sticking together

Standard heat preserving board, quickly assembled, combined closely, superior heat preserving effect

Evaporative temperature, -40C

Condensing temperature, +35C

Defrosting: water

Defrosting time: every 8–12 hours, last no more than 2 hours each time

Electronic control panel, controls the speed of the mesh-belt, processing time, displays the running speed and inner temperature.

|

DOUBLE SPIRAL FREEZER

|

|||||

|

Model

|

WLS-1000

|

WLS-1500

|

WLS-2000

|

WLS-2500

|

WLS-3000

|

|

capacity±10% (kg/h)

|

1000

|

1500

|

2000

|

2500

|

3000

|

|

Freezer room

size (meter) |

12.5×4.6*3.1

|

13.1×5.0*3.6

|

16.1×5.1*3.9

|

16.1×5.3*4.3

|

17.1×6*4.8

|

|

Cooling consumption(kw)

|

165

|

220

|

300

|

360

|

400

|

|

Installed power(kw)

|

20

|

24

|

32

|

40

|

46

|

|

Frozen time

|

15~90 mins (depends on one different food and different conditions)

|

||||

|

Note: 1. Spiral Freezer is based on freezing chicken. Loading density: 5.5 kg/m2, in feed temperature: +50, out feed temperature: -18, freezing temperature:-35±2.

2. Depending on the different products, the freezing time can be adjusted 3. Refrigerant capacity is counted on the base of +35 condensing temperature and -42 condensing temperature. 4. The technical parameters can be design nonstandard depending on the freezing food |

|||||

TWIN DRUM SPIRAL FREEZER

Freezing Capacity Range: 2,200-22,045 lb/hr or 1,000-10,000 kg/hr

Key Features: The Twin Drum Spiral freezer is designed to freeze a large quantity of products in less space, especially for products needing a long freezing time such as bulky foods, or raw poultry and meat. We can customize the freezing process to meet your various demands. The twin drum freezer is an ideal solution for mass production process.

Benefits:

- Pre-assembled and fully tested at our factory before shipping.

- Ready to be placed and connected to refrigeration, electrical and water service.

- Built to USDA, FDA, UL, CFIA, OSHA and CSA Specifications & Standards

- Continuous inline food freezing.

- Gentle, smooth handling of products.

- Compact design lowers operation cost and saves floor space.

- High efficiency allows for fast freezing.

- Minimum product weight loss by exposure to the lowest air temperature at all times.

- Stainless-steel construction.

- Easy access to sanitation and maintenance from all sides

- Multifunctional PLC system.

- Stainless-steel rails are covered with a UHMW polyethylene wear strip for many years of smooth and maintenance-free operation

- Modular Design for easy and quick on-site installation.

- Custom designs to fit your requirements

All seamless welded stainless-steel enclosure with robust welded steel support structure.

Customized airflow for efficient heat transfer.