Contact Belt Tunnel Freezer Manufacture by Advanced Freezers

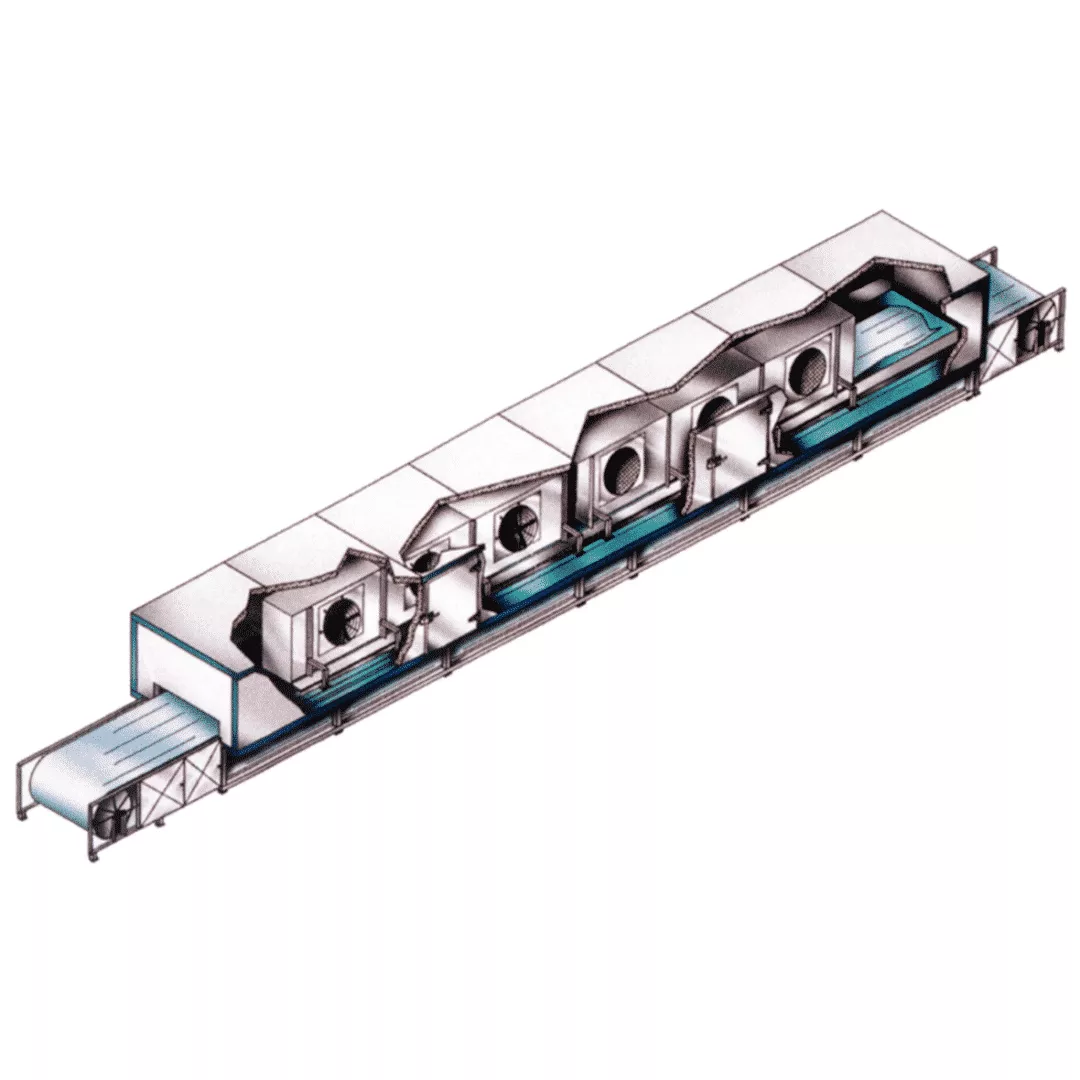

Contact Belt Tunnel Freezer

Pre-assembled at our factory, then fully tested to be easily assembled on-site. Contact Belt Tunnel Freezer Manufacture Advanced Equipment Inc. are designed for wet, fluid, or soft high-moisture or soft extruded products.

The CASCADE belt is a twin belt incline freezer providing positive conveying of products.

The product is mechanically agitated in a thin layer on the first belt, allowing it to be crust-frozen to seal the moisture and assure product separation. The product is transferred to the second belt, where it is accumulated in greater depth. In this stage, the product is further subjected to an upward airflow, and it is individually Fluidized and frozen completely. The Packaged Freezer has been pre-assembled and tested at our plant and is ready to be placed at your site.

The Freezer consists of a cold-rolled stainless-steel band, aluminum air units (evaporators), an insulated enclosure, a control panel, and supporting frames. It is assembled and pre-wired in modular sections for easy installation and future expansion in freezing capacity. The product is loaded manually or by a spreader shaker onto the stainless-steel band belt from one end. Then, the product travels into the tunnel sections, where the high-velocity blasts horizontally across the top of the product surface and under the belt. The horizontal air direction alternates from one section to the next to achieve even freezing. The frozen product then exits the tunnel sections, sliding off the belt smoothly without any marks. The product is frozen in the same form when loaded at the inlet end.

APPLICATIONS

Used for Wet, fluid or soft high moisture products or soft extruded products. Furthermore, cooked or fried products requiring no marking on product, such as fish fillets.

RED MEAT INDUSTRY — raw meat, hamburger patties

SEAFOOD INDUSTRY - raw scallops, fish fillets, raw shrimp

OTHER - products in trays at reduced capacity, products in slush or extruded forms

BENEFITS

Pre-assembled at our factory and fully tested

Easily assembled on site

Capable of a wide variety of product

Continuous inline food production

Gentle smooth handling of product

Lowest reliable operation cost

High-efficiency airflow and heat transfer

Expandable to a larger capacity

Easy access to sanitation and maintenance

Built to USDA, CFIA, FDA, OSHA, UL AND CSA – Specifications & Standards

LOW INVESTMENT

One of the most economical freezers offered in this class. Every component of the freezer evaporator, conveyor belting, and high-efficiency enclosure is manufactured in our highly experienced engineering and manufacturing facility. We can afford to pass on the savings to you, our valuable customer, without sacrificing quality.

FREEZING QUALITY

Assures excellent product freezing quality and reduced shrinkage loss by continuously agitating the product during the crust freezing stage and the fluidization freezing stage. The positive and precise conveying of the product throughout its freezing cycle assures positive even freezing times.

The more you know about freezers, the more you will look at advanced equipment inc. as your reliable supplier.

We hold key patents on IQF freezing that provide important advantages, combined with the fact that almost every part of the freezer in manufactured in in-house.