Energy efficiency in mechanical refrigeration systems for the meat industry

G. C. Briley

This paper describes various ways of increasing the efficiency of a mechanical refrigeration system. It compares the cost of operation with capital costs. The relative energy usage of the various cryogenic refrigerants is discussed in comparison to mechanical refrigeration systems. An analysis of the costs of chilling beef using conventional methods, hot boning methods, and a suggested chill pack (-2 °C) method indicates substantial savings in energy.

During the past three decades, most process industries have expanded energy instead of capital. It was always easy to justify the lowest price. Almost invariably, the low-priced refrigeration system had much higher energy requirements than the system with the higher cost. This approach was, and is, brought about by a tax system where energy is an expense and capital investment must be depreciated over a prolonged period. With low-cost energy, this approach is easy to justify.

Now, however, the cost of electricity and most other energy forms are increasing so rapidly that the plant owner is forced to start investing capital to conserve energy.

To put this into perspective, let us compare a mechanical freezing system that freezes 2727 kg (6000 Lbs of cooked meat portions per hour.

In 1970, this system would cost approximately $235 000 and require some 400 kW, including compression equipment and all ancillary fans, pumps, and other electrical requirements. In 1970, the cost of electricity was around 1 cents kWh, so a 4000 h year* operation had an electrical cost of about $17 000 yearly *(Table 1).

Table 1. Costings for a mechanical freezing

the system with a throughput of 2.7 tonnes/hour

| 1970 | 1979 | 1979* | |

| Mechanical system installed | $235,000 | $470,000 | $502,000 |

| Electrical energy costs | 1cent kWh* | 5cent kWh* | 5 kWh* |

| Cost for 4,000 hours of operation | $17 000 | $85000 | $68 000 |

| Operating cost as % of investment | 7.2% | 18% | 13.5% |

| Payback | Two years | ||

| * With an additional investment for energy savings |

In 1979, the capital cost became $470 000, and the cost of electricity rose by five to seven times. At 5 cents kWh* and a 4000 h year* operation, the electrical cost would be about $85 000 yearly *. At this point, the plant owner must start to analyze the cost of additional factors designed to reduce the electrical energy requirements. In most cases, a further investment of about 5% to 7% will reduce operating costs by 15% to 20%. As electrical rates increase from 8 to 104 kW', as in some areas, every plant owner will be forced to pursue every avenue to keep electrical operating expenses well below what most people have considered normal.

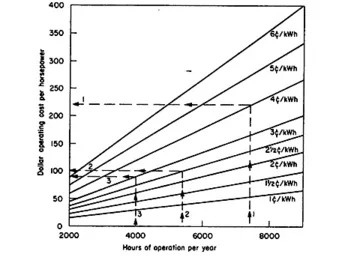

When you invest in a refrigeration system, power consumption is vitally important. Consider the possibility of 10% inflation per year, 20 years of plant life, a 92% efficient motor, 3q kW* electricity, and 24 h d operation. Under these conditions, 7.46 kW would cost approximately $153,740 in electrical energy over the next 20 years. If you only operate 2500 a year, instead of 8700 h, the cost is $44,178. Thus, when you analyze a refrigeration system, you should compare the total cost of owning and operating, not just the capital investment (Fig. 1).

The author is with the Refrigeration Engineering Corporation, 8799 Crown Hill, PO Box 3-C, San Antonio, Texas 78217, USA. This paper is based on one presented at the ASHRAE semi-annual meeting in Detroit. Mechanical refrigeration is the least expensive way to chill or freeze a food product,

Some ways in which the efficiency of mechanical refrigeration systems can be improved:

1. Select the most efficient refrigeration compression equipment available.

2. Select evaporators with ample coil capacity and install a demand-defrost system for defrosting all coils in rooms below 2°C. During hot gas defrost, an evaporator coil uses twice the energy used during regular operation, and this is under ideal conditions. Most existing defrost systems for evaporator coils are time-activated. Thus, many coils are defrosted much more often than required. Demand defrost initiated by the air pressure differential across the coil. As frost builds, the air pressure increases and activates the defrost cycle.

3. Install a sound oil management system. Remove the oil from the refrigerant before it gets to the evaporators. Oil in evaporators decreases evaporator efficiency, which in turn reduces system efficiency.

Hours of Operation Per Year

Fig. 1

Annual operating expenses for electric motor drives

Examples;

$1/HP x HP) /motor efficiency= operating cost per year: 1 - if 500 HP; 0.92 efficiency, 7400 h, operation @ 4 kWh* from graph s/HP = 220 then 1220 S/HP x 500 HP / 0.92 efficiency = $119 565 year-';

2 — if 100 HP; 0.92 efficiency, 5400 h, operation © 2 cents kWh' from graph S/HP = 100 then (100 S/HP x 100 HP)/0.92 efficiency = $10869 year';

3 — if 15 HP; 0.75 efficiency, 4000 h, operation © 3 cents kWh' from graph $/HP = 90 then 90 S/HP x 15 HP/0.75 efficiency = $1800 year-'.

Estimating motor efficiency: 0.92–100 HP and upwards; 0.88–20 HP to 100 HP; 0.85–5 HP to 20 HP; 0.75–1/2 HP to 3 HP.

Conversion factor to SI units: 1 HP = 0.746 KW.

4. Arrange the system for low condensing pressure during off-peak ambient conditions. Operating at a pressure of 687 KNM** (100 PSIG) during condensing instead of 1275 KNM** (185 PSIG) reduces the energy requirements' design value by 30% or more.

5. Install a programmable computer to control the entire refrigeration system. Properly programming all system functions to use the minimum amount of energy has reduced operating expenses dramatically.

6. Initiate a maintenance and operating system to efficiently use every kilowatt of electricity. Good maintenance of the refrigeration plant will reduce energy use.

7. If your plant requires hot water, a heat recovery system is another energy saver. This principle could be applied at the following stages; at high stage compressor discharge; booster compressor discharge; in the refrigerant condensing system; at the screw compressor oil cooler, and in the reciprocating and rotary compressor jackets.

In general, incoming water can be heated from 10 °C inlet to a maximum of about 60 °C. In an ammonia system, approximately 0.7 kWh of heat can be recovered for each compressor kWh power for boiler make-up, scalding systems, clean-up, domestic hot water, etc.

In most areas, a heat recovery system can be paid for out of savings in energy within one to two years. This payout time is rapidly reducing:

Mechanical refrigeration is the least expensive way to chill or freeze a food product. It uses less energy than any other system. Some basic comparisons between mechanical refrigeration, liquid carbon dioxide, and liquid nitrogen follow.

The costs of liquid carbon dioxide typically vary according to the plant location and transportation expenses. However, in general, the costs range from 24 pounds to 3 pounds for delivery, and as energy costs increase, these prices must rise. The production of liquid carbon dioxide is energy intensive. The electrical power required to produce liquid carbon dioxide equivalent to that provided by a mechanical system is more than double. And this is just the start. Some five to seven years ago, the cost of transportation of liquid carbon dioxide exceeded the cost of production. The cost of gasoline and diesel fuel is increasing even more rapidly. Liquid carbon dioxide costs will rise, and probably at a rate much faster than electrical costs.

Most of the same analysis applies to liquid carbon dioxide and liquid nitrogen. Liquid nitrogen is even more energy-intensive than liquid carbon dioxide. Here again, costs vary from 2 cents/pound to 5 cents/pound depending upon the proximity of liquid nitrogen production to the user, the local electricity costs, the competitive situation, and the quantity used. Liquid nitrogen is usually

designed to produce oxygen for a chemical or another process. Assuming that pure nitrogen is free, the electrical energy required to produce an equivalent amount of cooling as a mechanical system is approximately ten or more times the amount of cooling needed. Thus, the costs will rise much higher than those of mechanical systems. Again, liquid nitrogen is usually transported by truck or rail, and this cost is increasing rapidly.

In general, if we assume the costs of mechanical freezing may be scored as one, using liquid carbon dioxide would be scored as two or three, and with liquid nitrogen, the cost would be four or five.

For some reason, we in the refrigeration industry have been trying to freeze everything that comes along in the area of food products since 1848. It was discovered that food could be preserved by reducing its temperature to -17 °C and could be preserved for long periods. Frequently, we forget that not every item needs to be frozen to be preserved for the time to which existing distribution systems are geared. Every so often, we forget that the objectives are to provide a quality food product geared to the existing distribution system, keep the price at a minimum, and use the minimum amount of energy.

For many years, the poultry industry in the US distributed poultry in the form of whole birds packed in ice. This is not a very ingenious system, as each pound of ice-packed poultry requires about one-half pound of ice during transportation to the sales outlet. The temperatures of the delivered products were inconsistent and varied from 0 °C to 4 °C and above. Transporting 33.3 percent more weight than you sell is self-defeating and expensive. As a result, considerable research indicated that frozen poultry was the way of the future. However, some poultry producers decided to take a different approach. The demands of the supermarkets were directed toward prepackaged and pre-priced poultry, 'Ready for Sale.'

'Chill pack,' a product equilibrated at - 2 degrees C, was a good answer. Today, about half the US poultry pack is produced this way, and the percentage is rising. This product is produced by transporting the packages through a continuous freezer for a predetermined time, depending upon the package type. The average time is about 50 mm. The product is stored at -2 degrees C. This prepackaged product has a far superior shelf-life to ice-pack poultry.

Chill-pack poultry is produced using several types of automatic or semi-automatic systems. The selection of what will be used is related to the customer's product handling system. A semi-automatic system employs a multi-track tunnel freezer (Fig. 2), with each track driven independently by a variable speed hydraulic drive so that packages of different sizes and other time requirements can be chilled to -2 °C. Additionally, products can be frozen on one track while two tracks are used for the chill pack. The packages are transported through the tunnel in nesting plastic trays on a dolly. The dollies are then moved manually into a -2° C storage room that holds various production days. The product is unloaded from the dollies, pre-priced, packaged in a master carton, and loaded on the delivery truck.

Fig. 2

Multiple conveyor tunnel freezer

An automatic system typically employs a continuous freezer in which packages are transported through a -30 °C atmosphere of high-velocity air on a conveyor. This system requires that the packages be put in a master carton before storing in the -2 °C holding room. It is not as versatile as the tunnel freezer, as all sizes of packages are in the freezer at the same time. Although this system eliminates some labor, its capital cost is approximately double that of the tunnel freezer.

Some processors try to use blast freezers to produce chill packs. This is usually unsuccessful because it is most difficult to control the time that the product is in the freezer; thus, some of the product is frozen, and some is not properly chilled. Good chill pack products require precise control. The alternative to a chill pack product could be a frozen product. Let us compare the energy costs of each approach.

The heat removed from the bird for a chill pack is approximately 110 kJ kg*. For freezing, the heat removed is about 300 k J kg. From this relationship, you would expect the cost to be about 2.6 times more to freeze than to chill pack. However, considering all factors, the actual cost is about 2.3 times more. For example, using 34 kW electrical power, the energy cost of the chill pack is 0.13 cents kg, and for freezing, it is about 0.31 kg -. Capital costs for equipment would follow at a ratio of about 2.5 to 1 for a freezing system versus a chill pack system. Besides the reduced cost of production, the cost of transportation and storage for the chill pack is lower. For example, the relative energy cost for -2 °C storage versus -23 °C storage is about two to one, assuming identical heat loss. The basic difference is that the electrical requirements are 1.9 kWh IH* at -29 degrees C and -8 degrees C at 1.0 kWh TR* for all required electrical motors.

For many years, the red meat industry has been geared toward the distribution of an approximately 1.7 degrees EC product, either in carcass form or boxed.

Most recent studies regarding hot-boned beef indicate some interesting savings in energy costs. By eliminating the bones, excess fat, etc., the heat removal is reduced by 32% over intact sides of beef. Other factors affect the energy requirements and total savings using this system.

Assume that the hot-boned beef is vacuum packaged in portions of similar size and weight and boxed. Quick chilling in an automated carton freezing system (Fig. 3) would have advantages. It would minimize shrink, and the product could be chilled within eight to ten hours to -1.7 degrees C equilibrated, assuming air temperatures from -29 to -32 degrees C were used.

According to data published in the ASHRAE Data Book, conventional beef chill operations have net weight losses from 0.7% to 1% in the chill room and holding room losses from 0.6% to 1% for a 48-hour holding period, i.e., a total of from 1.3% to 2%. The hot bone and quick chill system should practically eliminate this type of shrink.

It is suggested that the product be chilled to approximately -1 to -3 degrees C and removed some 1/3 of the latent heat. The product should then be maintained at -1 to -3 degrees C during the distribution cycle. Little change would be required, as most trucks and stores could be operated in this range if they presently operate at 0.5 to 2 degrees C.

Most red meats take 20 to 25 days to get to the customer from the kill floor. Its shelf life is 2.5 times longer at 0.5 degrees C than at 4.5 degrees C. Using a chill pack system, the shelf life should be many times better. Due to the shortened chill time, the product could be delivered at least two to three days sooner.

Fig. 3 Carton freezer

Table 2. Cost comparisons for meat processing.

| Conventional Chilling | Chilling hot boned | Chill-pack | |

| Energy cost 1000* | $00.478 | $00.443 | $00.485 |

| Shrink | 1.3% - 2% | 0.3% -0.5% | neg |

| Time required h | 68–72 | 8–10 | 10–12 |

| Floor space required**, m sq. | 15000 | 3000 | 4000 |

| Yield | 68% -70% | 99% | 99% |

| * Based on 3 kW/electrical energy cost ** For 520 carcasses at 254 kg, 1560 lbs each |

|||

Little data is available on the use of chill packs in the meat industry in the United States. However, we anticipate a trend in that direction as energy costs increase. The result is as follows if we compare the cost of chilling beef conventionally with chilling hot-boned beef. Assuming 40.6 degrees C product in, and using the example in the ASH RAE Guide, (Chapter 28 (1978)) which describes a design for 520 carcasses weighing 254 kg each or 132 000 kg per beef chilled for 20h and held for 48 h, using .03 kW-' would cost approximately $139.00 l$1.05 -1) and take three days. Chilling hot-boned beef employs a compound compression system and an automated carton freezing system, and it is assumed that it will chill for ten hours from 40.6 degrees C to 1.7 degrees C. The cost for 132 t, less the 30% bones, trim, etc., would be about $90.00 (94 t-1, net or 6ft t-1, gross). This would be the same as the above cost (Table) 2).

This electrical energy saving of over 50% is paralleled by a reduction in space required from 1435 m2 to about 278 M2, a 60 h reduction in inventory requirements, and a reduction in capital investment. Depending upon the handling method, it is estimated that the automated hot-boned beef chiller could be installed for a capital cost of 10% to 20% less than a chill room and a 48-hour holding cooler. Labor would also be reduced, depending upon the packaging method and the chilling system employed.

Most importantly, as previously discussed, these savings are in addition to a 1% to 2% shrink saving.

The meat industry should move toward the chill pack to take advantage of additional shelf life and less spoilage. Based on the same example, the cost to chill pack at -2 degrees C, assuming removal of 70 kJ kg-1 of latent heat, would be about $1.07 t. Thus, we could chill pack for about the same energy we use now. The chill time would increase by two to four hours over the hot-boned chilling time. However, the installation costs should still be well below the conventional chill room/holding room methods.

The cost to freeze would be 2 to 2.3 times the cost to chill pack. The cost to store at -23 degrees C would be two to one versus -2 degrees C storage. It is recommended that air temperatures of -29 degrees C to -32 degrees C be employed for chilling a product to -2 degrees C as the low air temperature will seal the surface of the product rapidly and will eliminate much of the drip loss normally associated with chilling meat products. It will also decrease the chilling time and the initial cost of the conveying mechanism.

Conclusion

There are numerous ways to reduce the cost of energy in the meat industry. However, none are as promising as hot boning, chilling, and distribution at -1 degree C to -3 degree C. This 'system' would effectively reduce the energy cost of providing quality meat to the consumer by 30% to 40% over conventional methods