IQF Tunnel and Spiral Freezing for the Red Meat Industry

Advanced has been designing and manufacturing red meat IQF spiral freezing and IQF tunnel freezing systems for over 30 years. Decades of freezer research and development have made Advanced a globally recognized spiral and tunnel freezer brand.

Regarding meat IQF processes, read this article on IQF freezing Mechanical Efficiency in the Red Meat Industry.

Our engineers can easily tweak your tunnel freezer for maximum freezing performance. All our tunnel freezers are designed to be assembled in our factory, then disassembled and shipped to minimize site installation time. Advanced IQF freezers are designed to occupy minimal space, reducing the cost of ownership. All our spiral and tunnel freezers are built to USDA, FDA, UL, CFIA, OSHA, and CSA - Specifications & Standards.

Do you need an IQF freezer for meat products?

Call us, and an advanced engineer will answer any questions or concerns you may have. You can also schedule a free consultation on red meat IQF tunnel freezers.

CIP 'Clean In Place' system

Food safety in meat processing plants is often their highest priority. Consumers and plant management are aware that bacteria like listeria, salmonella, and E. coli can be found in meat.

Advanced IQF freezing tunnels help ensure that bacteria cannot hide. The secret is to create tunnel freezers for fast, easy, and efficient cleaning. Advanced freezers have over 30 years of experience manufacturing tunnel and spiral freezers—we are real experts.

Your Advanced IQF tunnel can have a CIP 'Clean In Place' system for disinfection and cleaning between production. We offer varied CIP systems depending on the type of tunnel freezer you wish to employ. Please call or email, and we will send you technical information on the tunnel freezer choices and cleaning options.

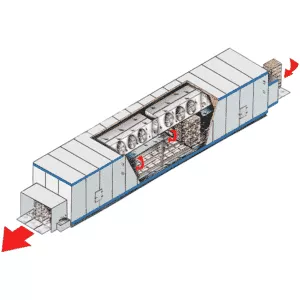

AAT BoxFreezer

The AAT BoxFreezer MRT/VRT tunnel is customized according to required capacity, dimensions and integration of the total production cycle from production to packing area. The AAT BoxFreezer MRT/VRT freezer system was carefully thought out! Saving space and achieving excellent adaptability.

High capacity

Variable/Multiple retention times

Cost-efficient freezing/cooling

High flexibility

Easy to clean

Mechanical reliable

Online support via internet

Up to 2000 units can be loaded and unloaded simultaneously.

Drag-thru-dolly Tunnel Freezer

The CASCADE belt is a twin belt incline freezer providing positive conveying of products. Assures excellent product freezing quality and reduced shrinkage loss

RED MEAT INDUSTRY: Primal, sub-primal, chubs, offal, packaged meats

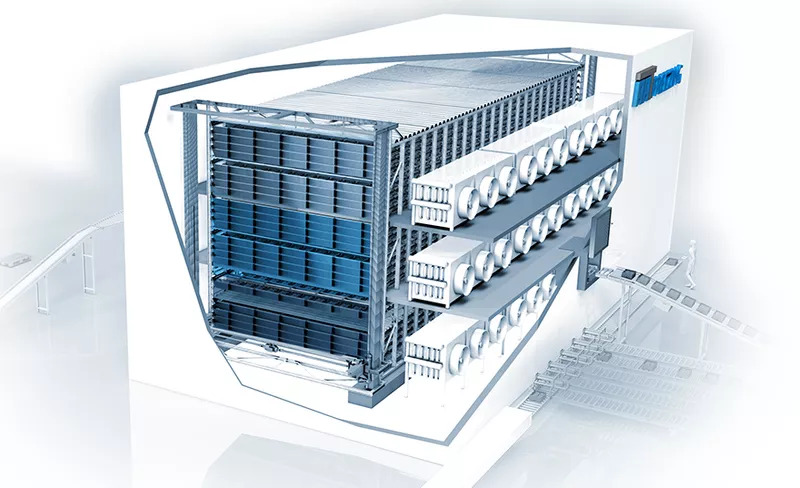

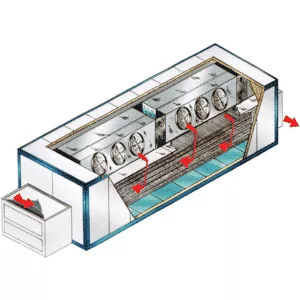

Multipass Belt Tunnel Freezer

The freezer is a continuous in-line-belt freezer designed to minimize product weight loss and assure quality gentle handling during the freezing process. Saving in processing floor space. Low operation cost.

RED MEAT INDUSTRY: Meatballs

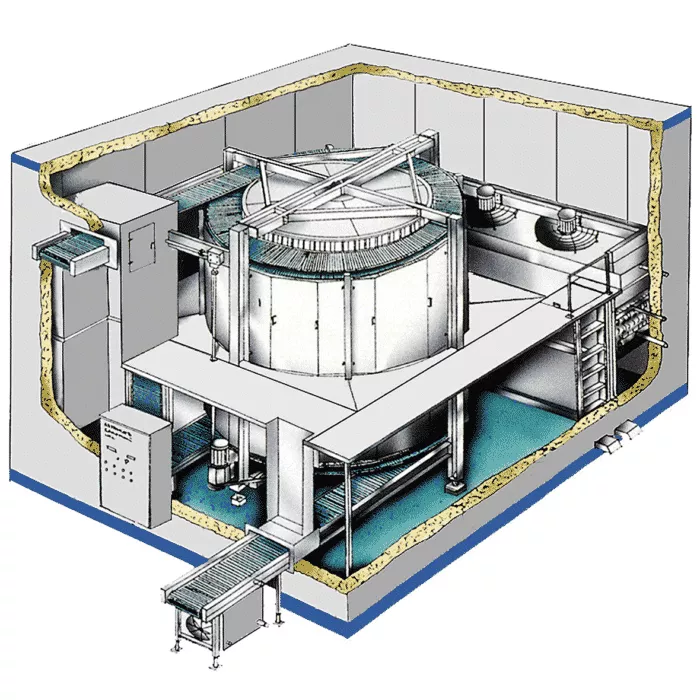

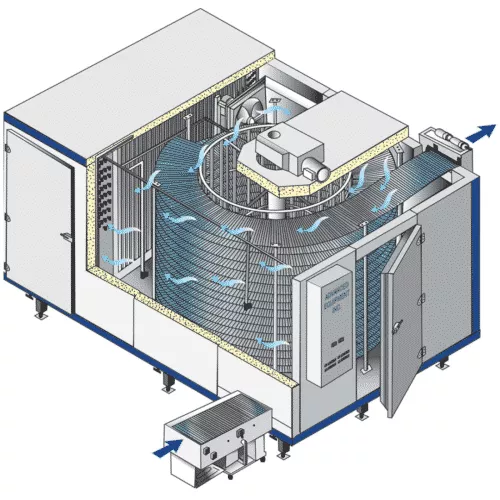

Packaged IQF Spiral Freezer

The Advanced Packaged IQF Spiral Freezer is a continuous in-line-belt freezer designed to minimize product weight loss and assure quality gentle handling during the freezing process.

RED MEAT INDUSTRY: meat patties, meatballs, raw hamburgers, breaded fried cuts, sausages, corn dog

Site Assembled IQF Spiral Freezer

Advanced Site Assembled IQF Spiral Freezer is a continuous in-line-belt freezer designed to minimize product weight loss and assure quality gentle handling during the freezing process. Completely factory assembled and designed to minimize site installation time.

RED MEAT INDUSTRY: meat patties, meatballs, raw hamburgers, breaded fried cuts