Advanced IQF Spiral & Tunnel Freezer Systems

Advanced Equipment Inc. has been designing and manufacturing both tunnel freezer and spiral freezer systems since 1986. Reliability, low maintenance expenses, superior sanitation features, custom solutions and a high return on investment are some characteristics of our spiral freezer systems. Advanced Equipment is established globally as one of the recognized leaders in advanced spiral technology among local, regional, national, International, and multinational frozen food producers.

For people new to tunnel freezers and spiral freezers: Advanced Equipment designs and manufactures Low-Temperature Mechanical Refrigeration IQF (Individual Quick Frozen) freezing systems for fast freezing various food products such as vegetables, fruits, poultry, red meat, bakery, and specially prepared foods in food processing plants.

Our tunnel freezer and spiral IQF freezer systems operate in virtually every food processing sector, including convenience foods, ready meals, frozen snacks, chicken, fish and poultry products, the bakery sector (frozen bread, cakes, and pastry products) and fruit, vegetables, etc.

-- The original ADVANCED FREEZER company --

For 37 years

manufactured IQF freezers.

Advanced Equipment Inc. is recognized worldwide for IQF freezing engineering.

A premiere IQF freezer manufacturer now with over 700 installations worldwide.

Tunnel Freezers and Spiral Freezers Models

NEWS: Advanced Freezers is named the Exclusive North American Distributor, AAT Box Freezers

BoxFreezer

$ Saving Food Plant Technology

Small BoxFreezer

Food Plant Modular Freezer

Advanced Equipment Inc. is the 'REAL' Manufacturer of Advanced Freezers

Owned and operated by REAL FREEZER ENGINEERS with the goal to create high-quality freezers with state-of-the-art technology.

Spiral Freezers – Tunnel Freezers

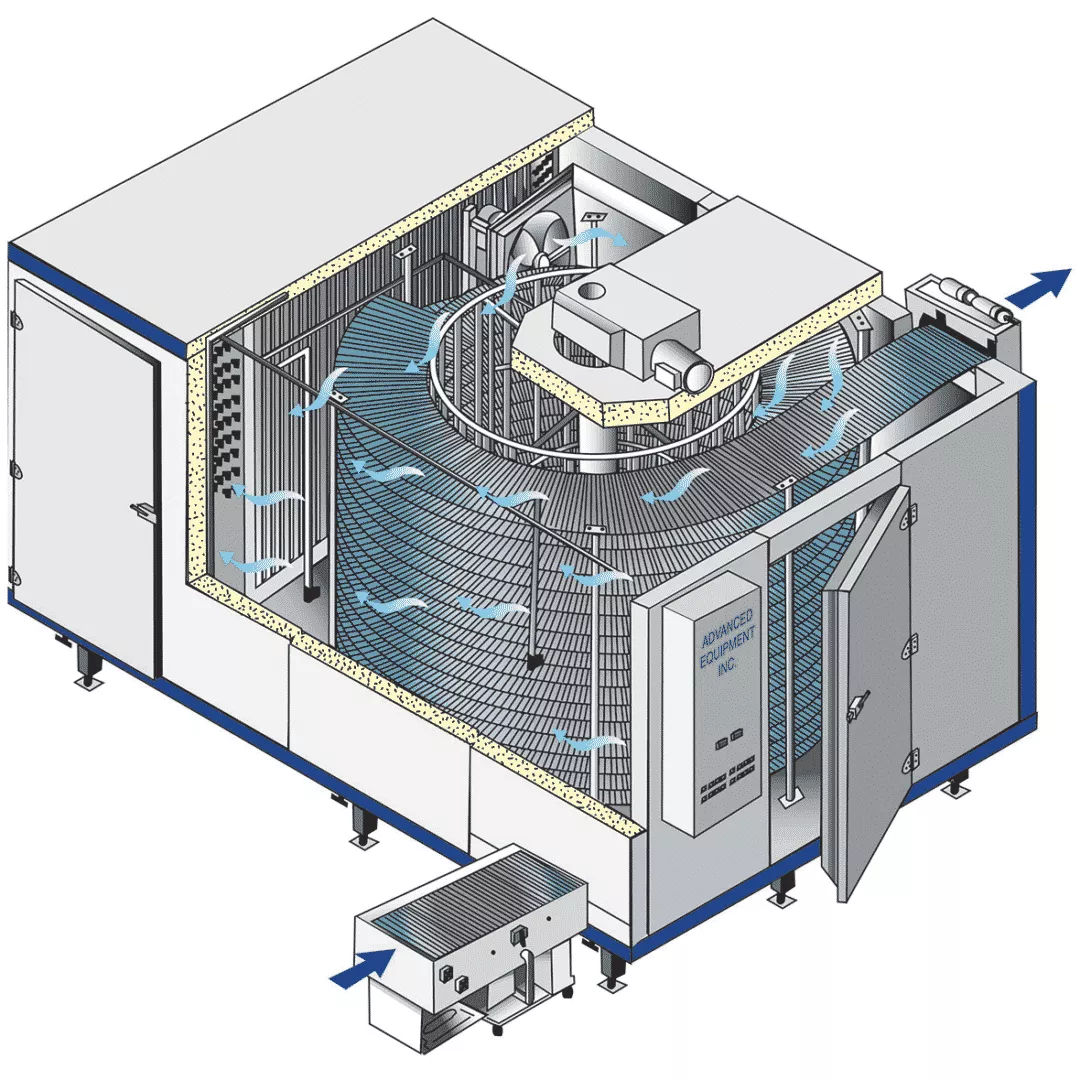

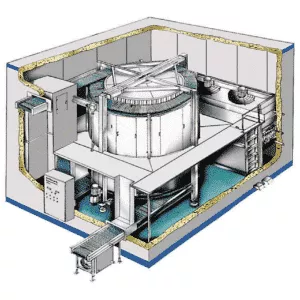

Advanced Equipment produces three different capacity ranges for our IQF spiral freezer. Our packaged spiral freezers process small capacity (1-2,000 lbs per hour) to medium capacity (8,000 to 10,000 lbs per hour) production levels. Our site assembled spiral freezer handles large capacities (Over 10,000 lbs per hour).

Advanced Equipment offers eight tunnel freezer versions that handle a wide range of food freezing processes. Our modular tunnel freezers allow you to expand freezing capacities without having to replace your existing freezer. Scalability is just one of the advantages of an Advanced tunnel freezer.

Advanced engineers have over 250 years of experience in the design and manufacturing of IQF tunnel and spiral freezers. Specialized expertise is why you can expect higher efficiency, less floor space, lower operating and equipment costs with an Advanced Equipment tunnel or spiral freezer.

Our clients have freezers still in service after 37 Years on the job!

YOU REALLY NEED TO HEAR WHY

---- Our CIP 'cleaning in place system' is 2nd to none period ----

Call for a consultation with a real freezer engineer and find out the advanced difference.

History by the Numbers

5 Continents

North America, South America, Asia, Africa and Europe have Advanced Freezers on site.

20 Countries

20 + Countries Worldwide have Advanced IQF Tunnel and Spiral Freezers in their food plants.

250+ Years

Years of Combined Refrigeration Engineering Experience.

Over 700 Installations

400 And Growing Installed Tunnel and Spiral Freezers

A Few of Our Larger Advanced Freezer Installations Sizes

- 20,000+ Lbs per hr - Soup Spiral

- 50,000 + Lbs per hr - Chicken Drag Tunnel

- 75,000+ Lbs per hr - one of the Biggest Tunnel Freezers in the World

Freezer Engineering

Advanced Equipment Inc. designs and manufactures Low-Temperature Mechanical Refrigeration IQF (Individual Quick Frozen) freezing systems for fast freezing various food products such as vegetables, fruits, poultry, red meat, bakery, and specially prepared foods in food processing plants.

Experience and Longevity

Since 1986, Advanced freezer systems have been recognized globally as one of the global leaders in IQF frozen food processing for Major Frozen Food Producers. Advanced has a proven track record with our reliable IQF tunnel and spiral freezers.

Meets Standards

Advanced Equipment Inc. freezers are designed and built to meet North American USDA, UL, CFIA, CSA and OSHA Standards for Safety, Sanitation, Maintenance and Accessibility.

In House Components

We manufacture most of our components in house to maintain quality control to produce the most economical and dependable freezers based on customer requirements. Most competitors buy parts and, when something breaks, they have to hope the supply chain can find and replace it. That can cause massive time shutdowns. We make components and can replace in house with minor time loss.