IQF Tunnel Freezer Manufacture Model Selector

Advanced Equipment Inc. IQF Tunnel Freezer Manufacturer USA, America, Canada sells new and used IQF tunnel freezers. As a IQF tunnel freezer manufacturer, Advanced Equipment Manufactures eight tunnel freezer versions for sale to handle a wide range of food freezing processes.

NEWS: Advanced Equipment Inc. is the exclusive North American Distributor of a State of the Art Carton Freezer

AAT BoxFreezer and AAT Small BoxFreezer

Advanced Freezers is an IQF tunnel freezer manufacturer with systems in the United States, Canada, and the globe.

Our tunnel freezers are factory-assembled and designed to minimize site installation time. Advanced tunnel freezers take up minimal space, reducing the cost of ownership. Whenever our engineers design and innovate, they consider reducing power consumption.

Advantages of Advanced Freezers

Advanced Equipment has your solution no matter what type of chicken or poultry products you need individually frozen.

Our spiral and tunnel freezers conform to the requirements and guidelines the USDA, FDA, UL, CFIA, OSHA, and CSA set forth.

We customize any of our spiral or tunnel freezers for unique freezing needs.

Every component of our freezers is manufactured in our sophisticated engineering and manufacturing facility to ensure quality control. Our spiral and tunnel freezers offer lower operation costs than C02, nitrogen, and other freezers. Advanced Equipment has been refining and improving our spiral and tunnel freezers for over three decades.

The Big Advantage

Spiral freezer and tunnel freezer with rock-solid reliability

If there is one factor that kills profit lines, it is downtime. Reliability is why our advanced freezer systems work in remote locations around the globe. Advanced Equipment is a globally recognized brand for spiral and tunnel freezers.

Advanced Equipment, a Tunnel Freezer Manufacturer, sells, modifies, and customizes IQF Tunnel freezers for the USA, America, Canada, and the World.

Free No Cost, No Obligation Prices

- For Budgeting Estimates

- For Buying Quotation

Get a Freezer Engineer's Consultation and Recommendation:

- Best for Food Industry

- Best For Your Budget

- Best For Future Expansion

- Best for Space in Your Plant

Spinach IQF Fluidized Freezer- Advanced Equipment Inc.

IQF Fluidized Tunnel Freezer for Fruit and Vegetable applications.

Built to USDA, FDA, UL, CFIA, OSHA, and CSA - Specifications & Standards

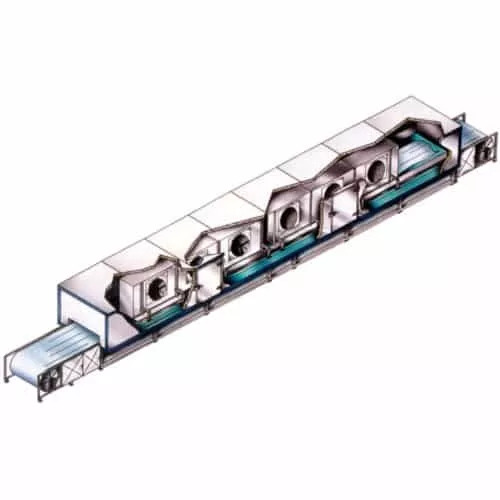

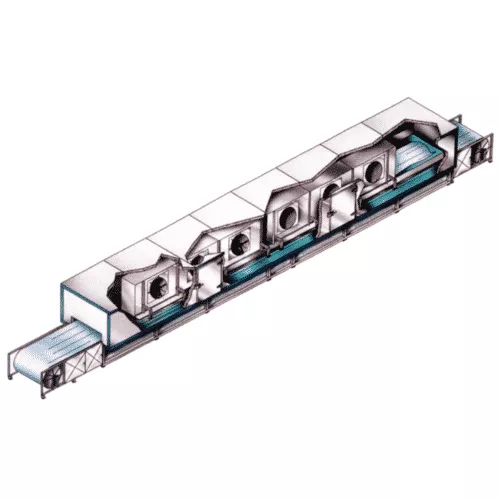

Packaged IQF Fluidized Tunnel Freezer

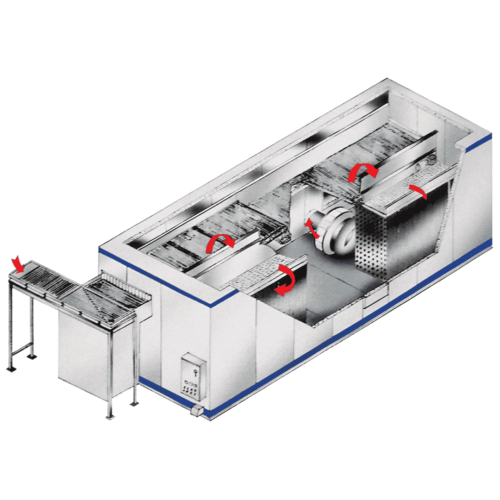

The CASCADE belt is a twin belt incline freezer providing positive conveying of products. The product is mechanically agitated in a thin layer on the first belt, crust-frozen to seal in the moisture. The packaged freezer is pre-assembled and tested at our plant, ready to be placed at your plant site.

This freezer is generally used for IQF. Small product particles range from 3/16 to 2 inches in diameter.

VEGETABLE INDUSTRY - peas, green beans, cut corn, mushrooms, vegetables, french fries, cob corn, diced carrots, diced onion, cut cauliflower, cut broccoli, cut asparagus, brussel sprouts.

FRUITS INDUSTRY - blueberries, cranberries, strawberries, cherries, gooseberries, raspberries, diced pineapples, sliced apple.

The seafood industry encompasses cooked shrimp, skin-on shrimp, and scallops.

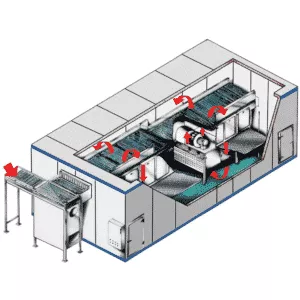

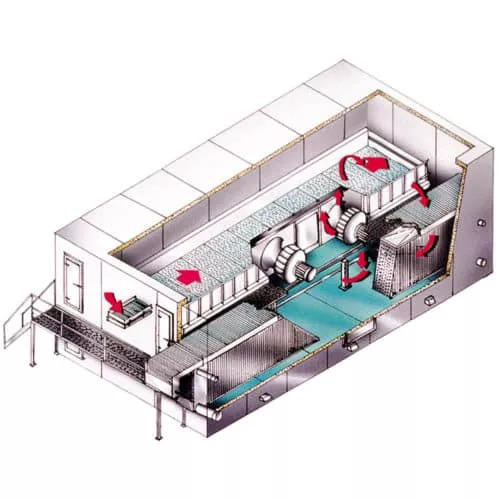

Drag-thru-dolly Tunnel Freezer

The CASCADE belt is a twin-belt incline freezer that provides positive product conveying. It assures excellent product freezing quality and reduces shrinkage loss. Equipped with two or three conveyor lanes, you can manually speed up or slow down each lane to meet any product needs. You can also chill or freeze three types of packaged products simultaneously. The belt is pre-assembled at our factory and fully tested to be easily assembled on site.

It is suitable for crust freezing or chilling tray-packaged parts continuously or deep-freezing the bulk parts and low grades overnight.

POULTRY INDUSTRY — chill packs

RED MEAT INDUSTRY — ideally adaptable to chill primal, sub-primal, chubs, and offal or freeze all types of packaged items

VEGETABLE INDUSTRY-freezes packaged asparagus, broccoli, brussel sprouts, etc.

SEAFOOD INDUSTRY — freezes large fish such as salmon.

Packaged Brine Tunnel Freezer

ADVANCED SEAL WELDED PACKAGED BRINE TUNNEL FREEZER combine compactness with a highly efficient conveying and freezing system, ideally suited to handle a wide variety of foods.

ADVANCED SEAL WELDED PACKAGED BRINE TUNNEL FREEZER are completely factory assembled, wired and tested, for minimum site installation time. Units are shipped in separated pieces and joined on the job site.

ADVANCED SEAL WELDED PACKAGED BRINE TUNNEL FREEZER are built to USDA, AMI, FDA, ASHRAE, UL, CSA cleaning, efficiency, and Safety Standards.

Optional items for cleaning, refrigeration control and evaporator defrosting are offered.

The Packaged Brine Shower/Glaze/Dryer Tunnel freezer is designed to freeze a wide variety of seafood products. Such as Shrimp, Fish, and others.

SEAFOOD INDUSTRY - Application is for saltwater seafood with skin protection only, as it enhances the taste.

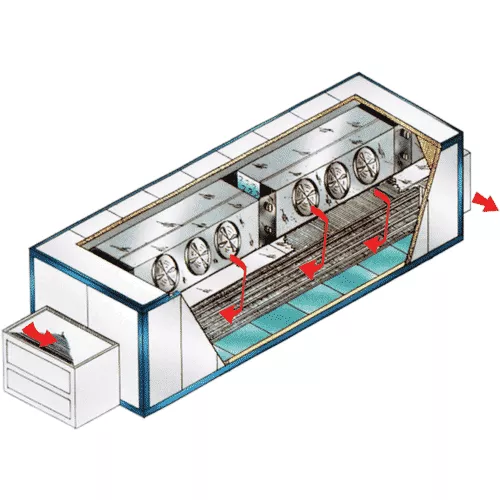

Modular IQF Fluidized Tunnel Freezer

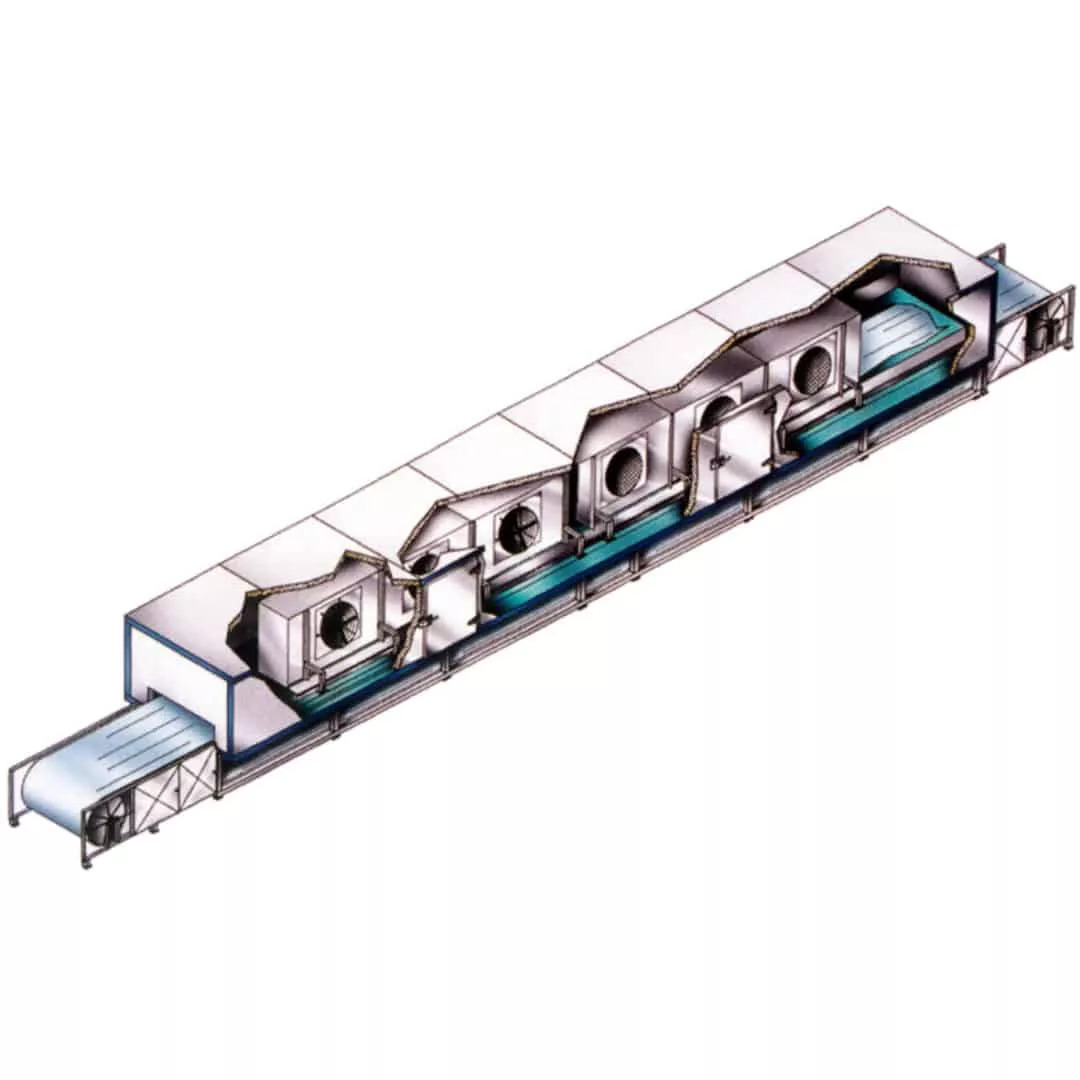

The CASCADE pass belt arrangement is an inline freezer providing positive conveying of product. The freezer is a continuous, cascade, inline, positive conveyed freezer that assures accurate freezing time and high freezing quality with low operation cost.

Generally used for IQF. Small product particle range from 3/16 to 2 inches diameter.

VEGETABLE INDUSTRY - peas, green beans, cut corn, mushrooms, vegetables, french fries, cob corn, diced carrots, diced onion, cut cauliflower, cut broccoli, cut asparagus, brussels sprouts.

FRUITS INDUSTRY - processed vegetables, fruits and special prepared foods

SEAFOOD INDUSTRY - cooked shrimp, skin on shrimp, scallops

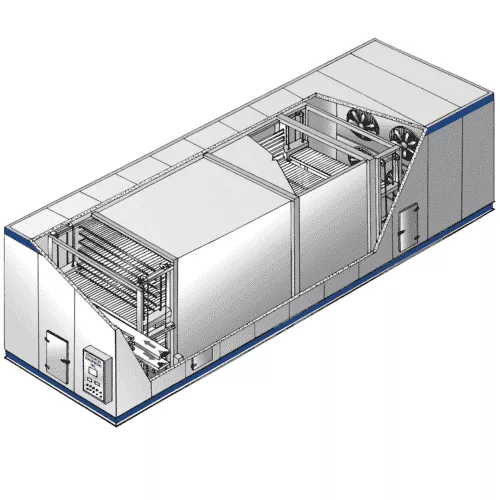

AAT BoxFreezer

NEWS: Advanced Equipment Inc. is the exclusive North American AAT Distributor!

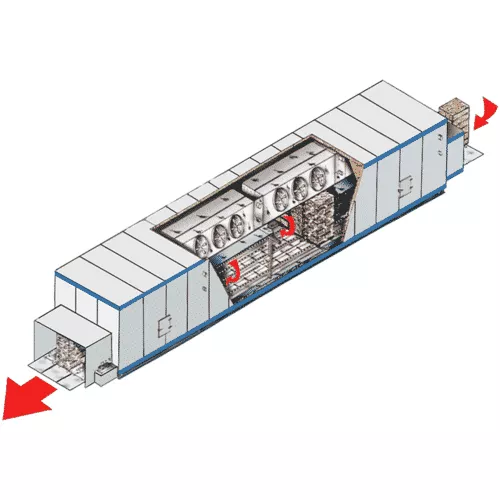

The AAT BoxFreezer MRT/VRT can handle volume requirements. The tunnel is customized according to required capacity, dimensions and integration of the total production cycle from production to packing area. The AAT BoxFreezer MRT/VRT tunnel for cartons was carefully thought out, saving space and achieving excellent adaptability.

- High capacity

- Variable/Multiple retention times

- Cost-efficient freezing/cooling

- High flexibility

- Easy to clean

- Mechanical reliable

- Online support via internet

- Up to 2000 units can be loaded and unloaded simultaneously.

Carton box freezers will handle all kinds of food products which require chilling or freezing, such as convenience food and ready-meals, snacks, ice cream, cheese, desserts, red meat, chicken and poultry, pork, seafood, fruit and vegetables, and pasta.

The freezers and chillers can also handle every type of packaging, carton boxes, crates, trays and containers of any kind in bulk.

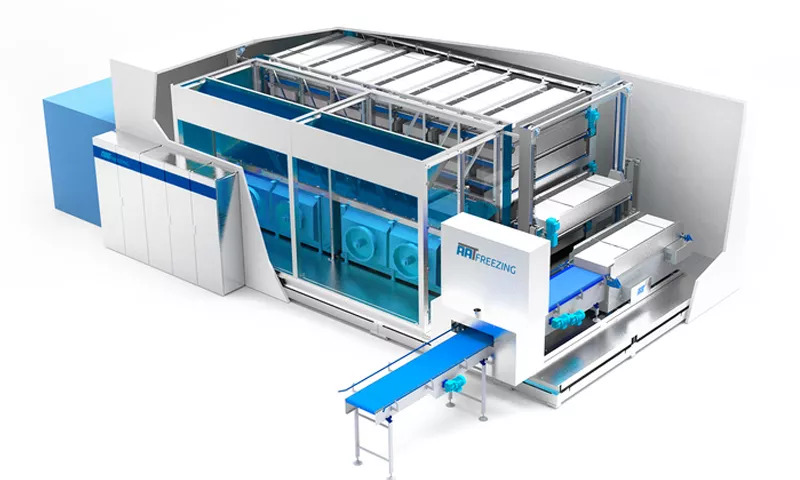

AAT Small BoxFreezer

NEWS: Advanced Equipment Inc. is the exclusive North American AAT Distributor!

We offer fully automated shock freezing systems, cooling systems, short-term storage systems and tempering systems for food in boxes or cartons.

One of the premium freezing systems on the market. These systems are automatically loaded with the products through an air lock.

After shock freezing, the finished products are automatically transported out. The Small BoxFreezer has a throughput of 100 kg to 2 tonnes per hour. As a result of specific adjustments, this is also compatible with the industry standard 4.0.

A very cost-effective, automated freezing system for products in small packaging or in small volume production such as cartons, crates, ice cream containers, dairy products, convenience food etc. The system is ideal for products with different freezing times.

Impingement PolyBelt Tunnel Freeze

The IMPINGEMENT PolyBelt TUNNEL FREEZER utilizes a solid flat top polyethylene belt, which allows for gentle handling of the product and leaves no surface marks. High-efficiency evaporators and fans, with a combination of concentrated air jets, are used to achieve fast freezing time with minimum dehydration of the product. The entire system is enclosed in a stainless-steel finished high efficiency insulated enclosure.

Completely packaged and ready to be moved into place. All that is needed is to install the belt and connect services such as electric power, water, and refrigeration

Designed to freeze a wide variety of wet and soft products. Products such as raw meat, fish fillet, scallops, shrimp, squid and extruded products.

Multipass Belt Tunnel Freezer

The freezer is a continuous in-line-belt freezer designed to minimize product weight loss and assure quality gentle handling during freezing. Completely factory assembled and designed to minimize site installation time.

Designed to freeze or chill any product. Product larger than 1/2 inch round or thick without any surface moisture, such as Italian Pasta product, fried breaded/battered product.

POULTRY INDUSTRY - chicken parts, chicken nuggets

RED MEAT INDUSTRY - meatballs

SEAFOOD INDUSTRY - fish sticks, raw shrimp, fish fillets

Tray Fluidized Tunnel Freezer

The Perforated Tray Tunnel System utilizes a combination of horizontal and vertical pulsating air, continuously turning the product.

Pre-assembled and tested at our plant, it is then disassembled in sections for shipping, and quickly reassembled at your site.

This tray tunnel freezer is designed to freeze a wide variety of delicate products.

POULTRY INDUSTRY - diced chicken chunk

RED MEAT INDUSTRY - meatballs

VEGETABLE INDUSTRY - peas, cut corn, diced carrots, diced mushrooms, diced spinach, cooked rice, pasta product

SEAFOOD INDUSTRY - cooked shrimp, scallops

Contact Stainless-Steel Belt Tunnel Freezer

ADVANCED CONTACT BELT TUNNEL FREEZER consists of cold-rolled stainless-steel band, aluminum air units (evaporators), insulated enclosure, control panel and supporting frames. Completely assembled and pre-wired in modular sections, for easy installation and for future expansion in freezing capacity. Pre-assembled at our factory and fully tested to be easily assembled on site

Used for IQF. Wet, fluid or soft high moisture products or soft extruded products. Also, cooked or fried products requiring no marking on product, such as fish fillets.

RED MEAT INDUSTRY - raw meat, hamburger patties

SEAFOOD INDUSTRY - raw scallops, fish fillets, raw shrimp

OTHER - products in trays at reduced capacity, products in slush or extruded forms

Impingement PolyBelt Tunnel Freeze

The IMPINGEMENT PolyBelt TUNNEL FREEZER utilizes a solid flat top polyethylene belt, which allows for gentle handling of the product and leaves no surface marks. High-efficiency evaporators and fans, with a combination of concentrated air jets, are used to achieve fast freezing time with minimum dehydration of the product. The entire system is enclosed with a stainless-steel finish high efficiency insulated enclosure.

Completely packaged and ready to be moved into place. All that is needed is to install the belt and connect services such as electric power, water, and refrigeration

Designed to freeze a wide variety of wet and soft products. Products such as raw meat, fish fillet, scallops, shrimp, squid and extruded products.

Variable Time Tunnel Freezer

UNDER CONSTRUCTION

Modular Tunnel Freezers = Scalability

Advanced modular tunnel freezers deliver SCALABILITY. As you grow your business and freezing process capacities need to increase, you can simply add a new section (modular tunnel freezer) without any major production interruptions. Our modular freezers allow you to expand your freezing capacities without having to replace your existing freezer.

Our designers can also help you plan for the future. If we have an idea of your future expansion plans, we can make minor modifications that will save you a LOT of money in the future.

The Advanced Advantage

For over 40 years, Advance Equipment has been a leading innovator in food production freezer systems. Basically, our worldwide reputation is that our freezer systems are built like tanks that deliver years and years of use with minimal maintenance and lower operating costs.

Power consumption, for example, is a crucial cost factor, especially in some countries with exorbitant power rates. Whenever our engineers design and innovate, they have their eye on power consumption.

Sanitation is another important consideration, especially considering the cost of recalls and subsequent legal actions. Advanced is obsessive compulsive when it comes to hygiene standards. We not only have solved the sanitation problems inherent with tunnel systems, we have simultaneously lowered cleaning maintenance costs and the cost of ownership.

Rock Solid Reliability is mission-critical to prevent downtime. If there is one factor that kills profit lines, it is downtime. Reliability is the main reason you will find Advanced freezer systems in over 20 countries.

There are numerous other advantages Advanced Equipment brings to the table. The bottom line is Advanced Freezer Systems deliver a high ROI.

CIP 'Cleaning in Place' Technology

Advanced freezer appreciates that cleanliness is a priority for food plants. Our freezers offer our own CIP 'Cleaning in Place' Technology along with over 30 years of reliable food freezing equipment for seafood processors.

What are You Waiting For?

Give us a call and one of our freezer system experts can answer any questions and show you an advanced solution that covers your needs. You can also schedule a free introductory consultation on a new or used tunnel freezer.