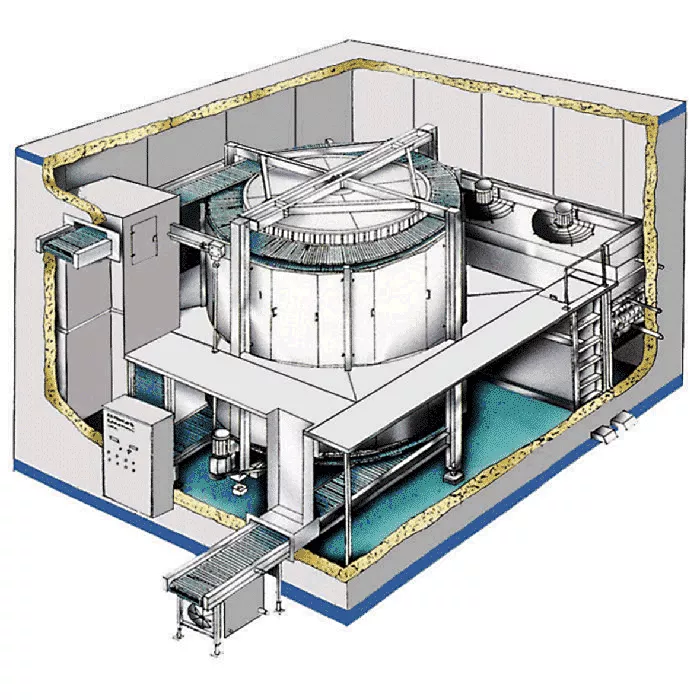

Factory Built, Site Assembled IQF Spiral Freezers

Site Assembled Spiral Freezers at food plants

Advanced IQF Spiral Freezer Manufacturer of factory built, factory tested then site assembled IQF (Individual Quick Freezing) spiral freezers primarily used by companies that process 10,000 or more lbs of product per hour. We also have two smaller capacity spiral freezers. Many IQF industry standard spiral freezer designs and features were pioneered by Advanced Equipment. When it comes to high-capacity performance, dependability and low ownership cost, you can’t go wrong with an Advanced site assembled spiral freezer.

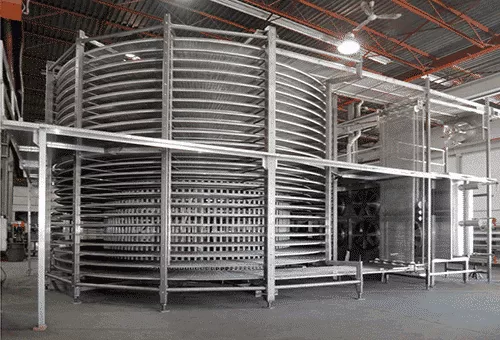

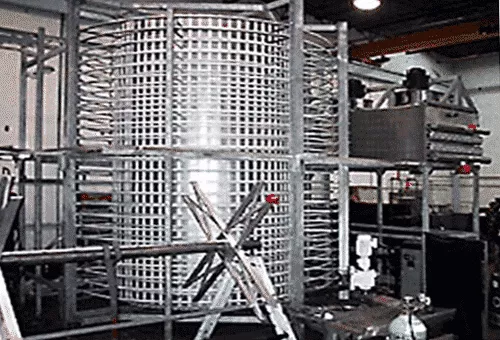

Advanced spiral freezers manufactured in North America are completely factory assembled, tested and disassembled into components for easy shipping to the plant for re-assembly. Frame & Belt supports can be constructed with economical Hot Dipped Galvanized Steel, or a fully Stainless-Steel version. All our spiral freezers are built to USDA, UL, CFIA, and CSA standards. Advanced has built some of the largest Spiral IQF freezer systems in the world. No matter how much production volume you may need, Advanced can design, build and install any size spiral freezer.

Free No Cost, No Obligation Prices

- For Budgeting Estimates

- For Buying Quotation

Get a Freezer Engineer Recommendation:

- Best for Food Industry

- Best For Your Budget

- Best For Future Expansion

Site Built Spiral Freezer - Advanced Equipment Inc.

Designed for Large Capacity or Difficulty to Move in Place

The freezer is a continuous in-line-belt freezer designed to minimize product weight loss and assure quality gentle handling during the freezing process.

Built to USDA, FDA, UL, CFIA, OSHA, and CSA - Specifications & Standards

IQF Spiral Food APPLICATIONS

- POULTRY INDUSTRY - chicken parts, chicken patties, chicken nuggets, marinated chicken chunk, breaded chicken parts

- RED MEAT INDUSTRY - meat patties, meatballs, raw hamburgers, breaded fried cuts

- SEAFOOD INDUSTRY - breaded fish sticks or patties, raw shrimp, fish fillets, scallops, whole fish

- BAKERY PRODUCTS - pizza crust, pie, cookies, pasta, bread dough

- PREPARED FOODS - packaged food in trays, shrimp in trays, ice cream cups, products requiring a long retention time.

Our Spiral Freezers Save Space

Advanced Equipment is an IQF Spiral Freezer Manufacturer offering site assembled spiral freezer as it is a continuous in-line-belt freezer designed to minimize product weight loss and assure quality, gentle handling during the freezing process. Products are fed evenly from the production line directly onto the loading freezer belt. The belt quickly transports the product into the low temperature-freezing zone. The belt spirals up along the rotating drum until it reaches the top, where the frozen product is gently discharged from the freezer discharge port.

Due to the large spiral belt surface available, products can be frozen in single layers, or individually for IQF freezing quality. Because products can maintain their original load-in position throughout the freezing process, sorting of the simultaneously frozen mixed products is simplified. Yet another space and cost-saving feature with the Advanced spiral freezer.

Our IQF spiral freezers feature a conveyor system that consists of a continuous stainless-steel belt wrapped around a rotating drum, moving in a refrigerated environment. Our spiral freezers can utilize the most vertical space. If you are restricted by limited floor space, your perfect candidate is an Advanced spiral freezer.

IQF Spiral freezer manufacturer of factory built, factory tested packaged spiral freezers

Advanced site assembled IQF (Individual Quick Freezing) spiral freezers are primarily used by companies that process 10,000 or more lbs of product per hour. We also have two smaller capacity spiral freezers. Many IQF industry standard spiral freezer designs and features were pioneered by Advanced Equipment. When it comes to high-capacity performance, dependability and low ownership cost, you can’t go wrong with an Advanced site assembled spiral freezer.

Completely factory built, then TESTED and disassembled into components for easy shipping to the plant for re-assembly!

Advanced spiral freezers are completely factory assembled, tested and disassembled into components for easy shipping to the plant for re-assembly. Frame & Belt supports can be constructed with economical Hot Dipped Galvanized Steel, or a fully Stainless-Steel version. All our spiral freezers are built to USDA, UL, CFIA, and CSA standards. Advanced has built some of the largest IQF freezer systems in the world. No matter how much production volume you may need, Advanced can design, build and install any size spiral freezer.

Spiral Freezer Advantages

Since 1986, Advanced Equipment has been a global brand with freezer installations around the world.

Here are some of the advantages when you buy an Advanced site assembled spiral freezer:

Low operation costs compared to C02, nitrogen and other freezers. This is achieved by utilizing the most efficient mechanical refrigeration method, combined with our new unique low-pressure, high velocity, horizontal airflow recirculation system. The horizontal airflow assures that heat is continuously removed from all surfaces of the product.

Low investment makes Advanced Freezers one of the most economical spiral freezers offered in its class. Every component of the freezer is manufactured in our well-equipped engineering and manufacturing facility; we can afford to pass on the savings to our customers without sacrificing quality.

Superior design. We begin with a standard design that is carefully developed to meet most standard needs. However, we also custom design our equipment to individual customer’s requirements.

Clean In Place CIP system

Sanitation and reduced cleaning costs. Our 'Clean In Place' system assures product safety at every point of the freezing process. Our cleaning system saves downtime and increases productivity, resulting in substantial savings. The Advanced CIP System provides a sanitary design for high-efficiency, energy-saving cleaning solution for reduced operating cost, ease of cleaning and dependable trouble-free production.

Are you ready to consider moving up to an Advanced Spiral Freezer?

Give us a call and an Advanced spiral freezer expert can guide you through our simple Implementation process for spiral freezers. You can also schedule a free no obligation consultation on buying an Advanced spiral freezer