IQF Spiral and Tunnel Freezers for the Seafood Industry

Our IQF Freezers save Time and Money

With the Advanced IQF freezer cleaning system (CIP), all you have to do is press one button and the system automatically cleans your spiral or tunnel freezer. Our automatic cleaning systems run on washing cycle timers like a modern washing machine.

Complete integration of our freezer cleaning system ensures automatic and trouble-free cleaning with higher economic efficiency. Advanced Cleaning-In-Place (CIP) and Sterilization-In-Place (SIP) systems provide automatic cleaning and disinfecting without major disassembly and reassembly. This is why Advanced Freezer Customers enjoy minimal downtime and lower labor costs with our spiral and tunnel freezers.

Are you looking for a way to quickly freeze seafood?

Advanced freezer manufactures various Tunnel and Spiral freezers for the seafood industry. Depending on the seafood processing needs, an Advanced Engineer can help you pinpoint the IQF freezer solution that is the right fit for your seafood freezing needs.

Give us a call and an Advanced refrigeration engineer can answer any question you may have on our seafood spiral and tunnel freezers. You can also schedule a free consultation on our spiral and tunnel freezers.

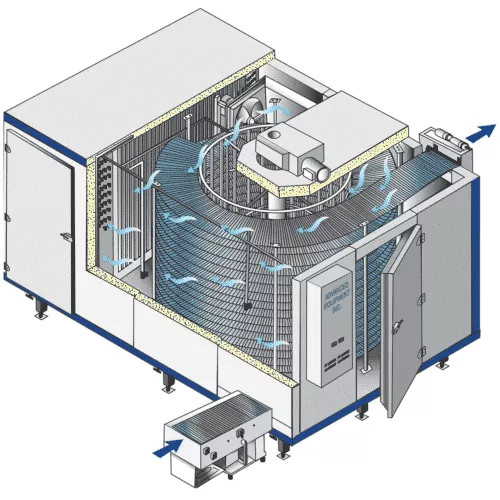

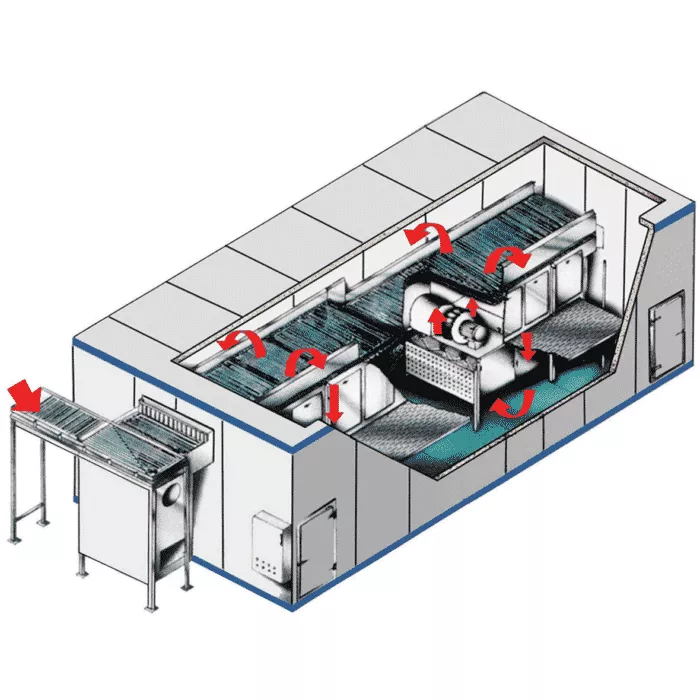

Packaged IQF Spiral Freezer

Advanced IQF Spiral Freezer is a continuous in-line-belt freezer designed to minimize product weight loss and assure quality gentle handling during the freezing process.

SEAFOOD INDUSTRY: Raw or breaded fish sticks or patties, shrimp, fish fillets, scallops, whole fish

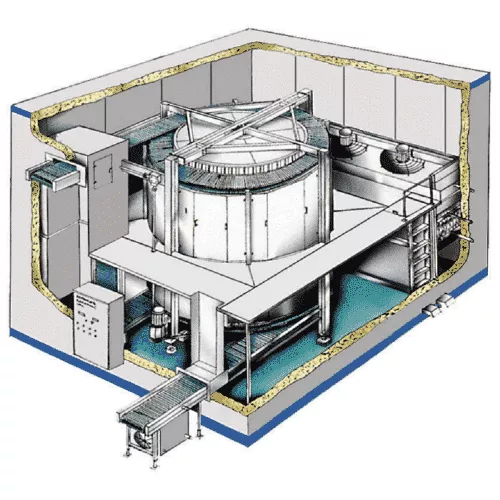

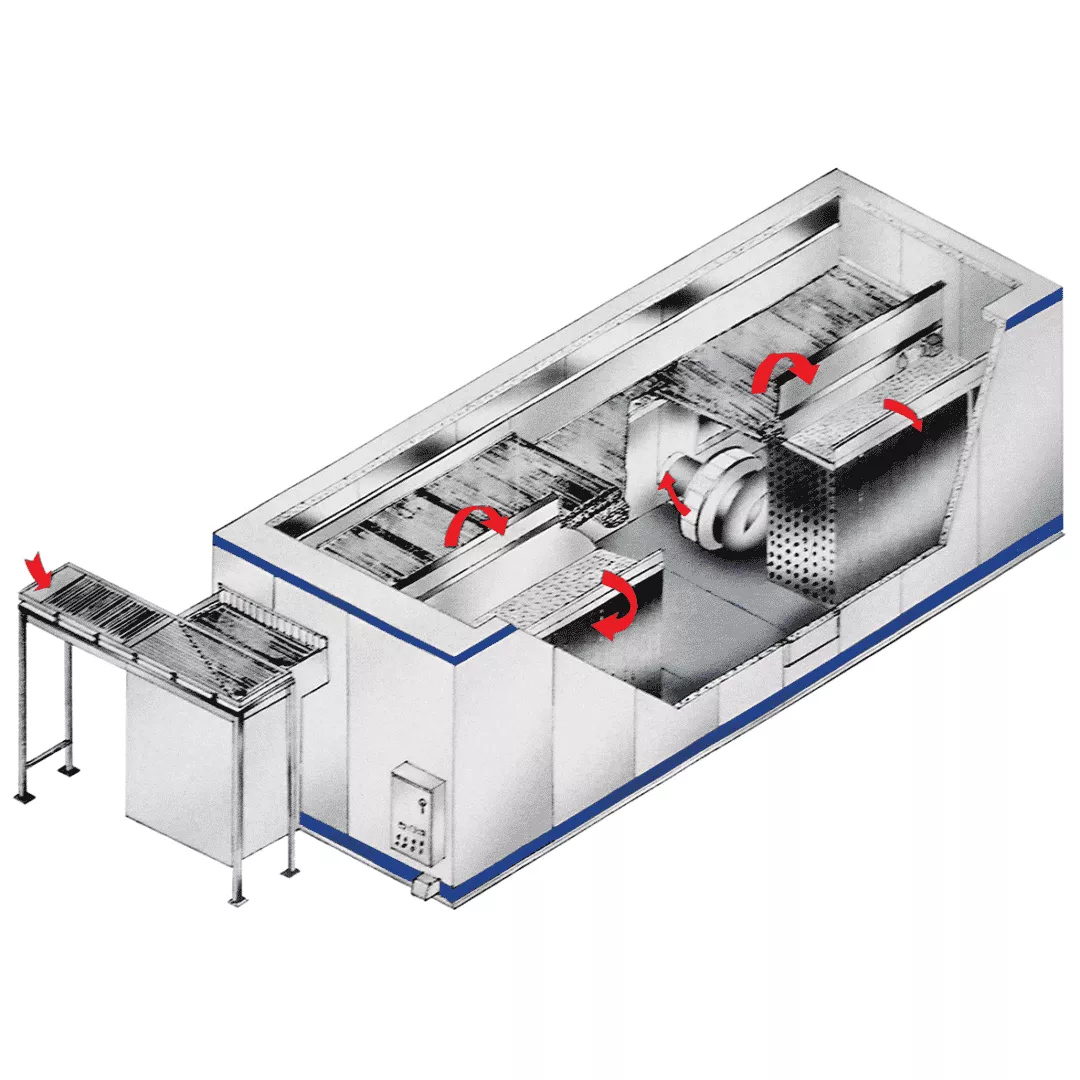

Site Assembled IQF Spiral Freezer

Advanced Site Built IQF Spiral Freezer designed to minimize product weight loss and assure quality gentle handling during the freezing process. Completely factory assembled and designed to minimize site installation time.

SEAFOOD INDUSTRY: Raw or breaded fish sticks or patties, shrimp, fish fillets, scallops, whole fish

Modular IQF Fluidized Tunnel Freezer

The CASCADE pass belt arrangement is an inline freezer providing positive conveying of product. The freezer is a continuous, cascade, inline, positive conveyed freezer that assures accurate freezing time and high freezing quality with low operation cost.

SEAFOOD INDUSTRY: Cooked or raw shrimp, skin-on shrimp, scallops

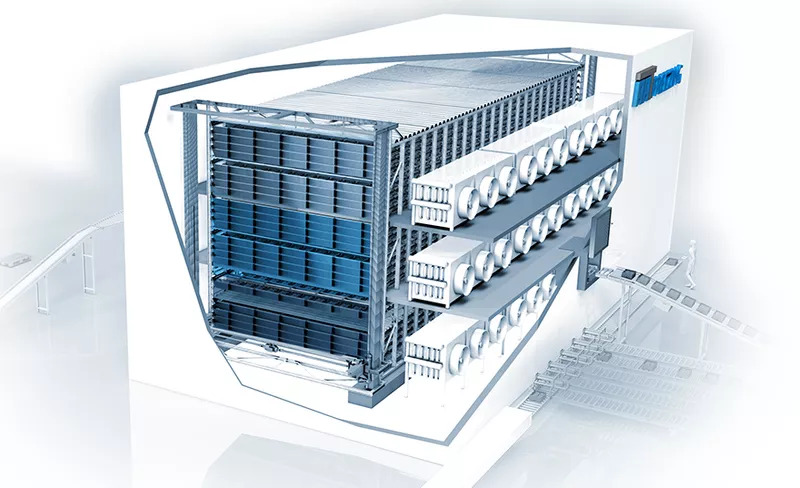

AAT BoxFreezer

The AAT BoxFreezer MRT/VRT tunnel is customized according to required capacity, dimensions and integration of the total production cycle from production to packing area. The AAT BoxFreezer MRT/VRT tunnel was carefully thought out! To save space and achieve excellent adaptability.

- High capacity

- Variable/Multiple retention times

- Cost-efficient freezing/cooling

- High flexibility

- Easy to clean

- Mechanical reliable

- Online support via internet

- Up to 2000 units can be loaded and unloaded simultaneously.

Packaged IQF Fluidized Tunnel Freezer

The CASCADE belt is a twin belt incline freezer providing positive conveying of products. Assures excellent product freezing quality and reduced shrinkage loss

SEAFOOD INDUSTRY: cooked shrimp, skin on shrimp, scallops.

Drag-thru-dolly Tunnel Freezer

The CASCADE belt is a twin belt incline freezer providing positive conveying of products. Assures excellent product freezing quality and reduced shrinkage loss

SEAFOOD INDUSTRY: freezes large whole fish such as salmon, cod, halibut

Impingement PolyBelt Tunnel Freezer

The Advanced Impingement PolyBelt Tunnel Freezer utilizes a solid flat top polyethylene belt, which allows for gentle handling of the product and leaves no surface marks. Ready to be moved into place.

SEAFOOD INDUSTRY: Scallops, fish fillets, shrimp

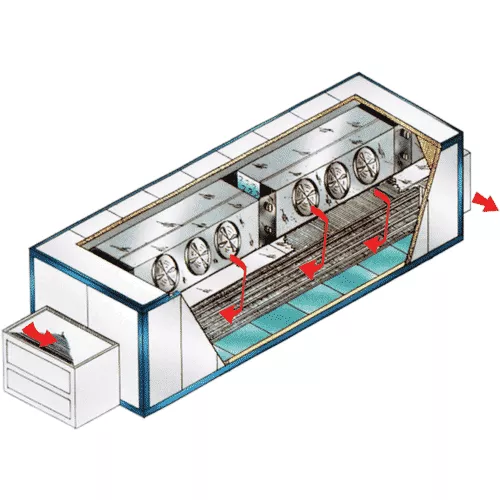

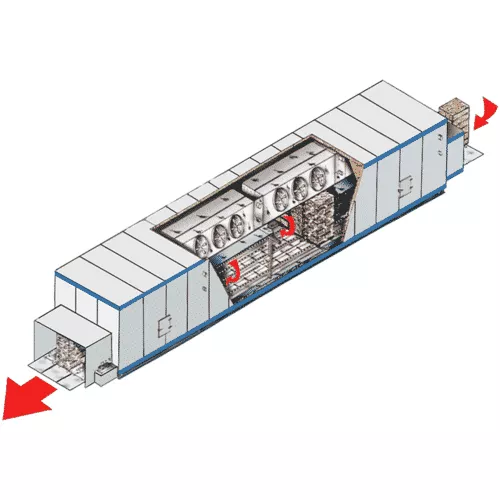

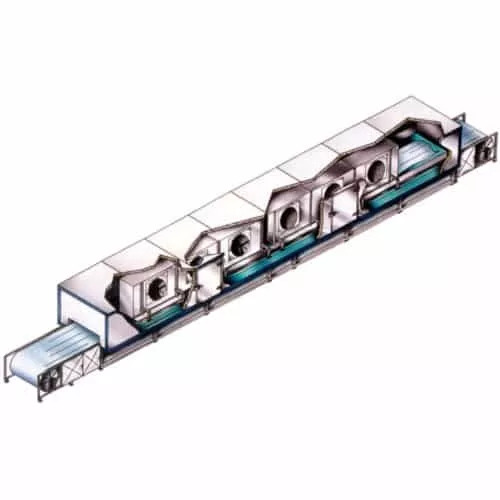

Multipass Belt Tunnel Freezer

The freezer is a continuous in-line-belt freezer designed to minimize product weight loss and assure quality gentle handling during the freezing process. Saving in processing floor space. Low operation cost.

SEAFOOD INDUSTRY: capable of a wide variety of products cooked shrimp, skin on shrimp, scallops