AAT BoxFreezer

NEWS: Advanced Equipment is the Exclusive North American Distributor for BoxFreezers for

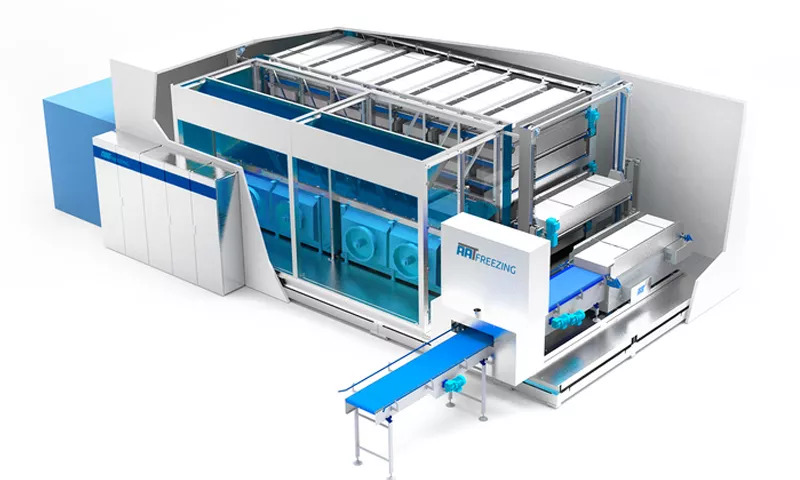

Customized carton-type freezer tunnels are available!

With high capacity, MRT (Multiple Retention Time) and VRT (Variable Retention Time)

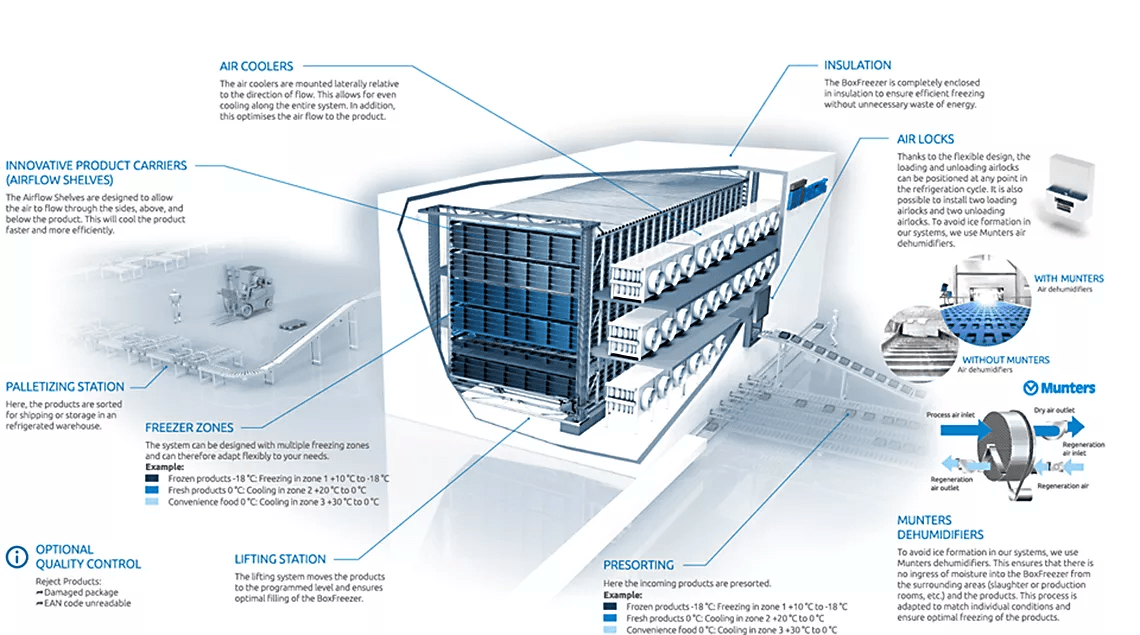

Features and Innovations

AAT BoxFreezer can freeze or chill your products in cartons, plastic totes, or shrink wrap. Our tunnel carton freezer ensures rapid freezing, which preserves your products optimally. Any packaged product - cartons, boxes, trays, or bulk containers

The pre-sorting system with the advanced freezing unit combined with the output distribution contributes to product quality while lowering labor costs.

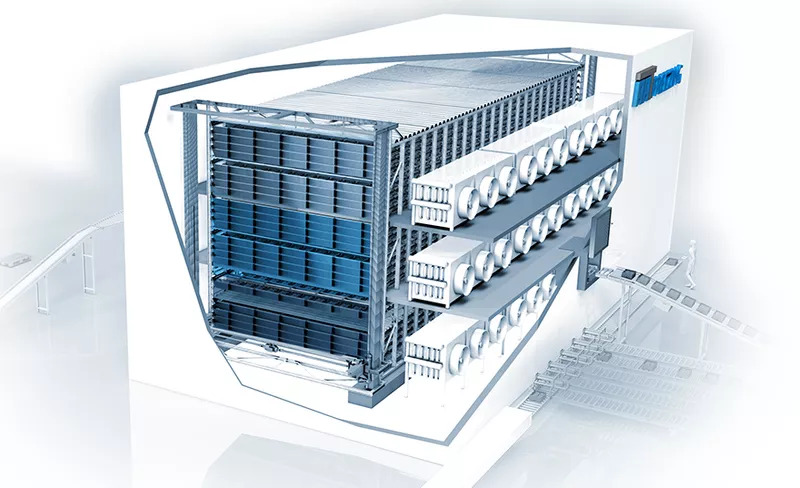

The AAT BoxFreezer freezes or chills large quantities of boxed products of different sizes simultaneously. Plus, we can automate your production line to loading dock process and save labor dollars with AAT BoxFreezer.

Boost Profits—imagine the Savings on power and labor costs with the flexibility of 3 freezing zones. Plus, staff can walk into the freezer while running to any part of the freezer!

Features of AAT BoxFreezer SRT, MRT, VRT Tunnel

Single Retention Time Tunnel and Variable Retention Time Tunnel

offer temperature control with the ability to handle different products simultaneously.

Fully Customized

We manufactured according to the required capacity, dimensions, and integration of the total production cycle from production to packing area.

Due to the flexibility of construction for the individual tunnel, you gain optimum utilization of available space, which is very difficult with other types of tunnels, where the customer has to adjust available space to the tunnel.

Our tunnel freezer's energy-efficient design meets industry requirements while saving you money on your power bill and boosting your profit.

We listen to our customers. Necessity can be the origin of great, new, innovative features. Since 1986, we have been improving our freezer systems.

Efficient Horizontal airflow freezing

A Carton freezer minimizes retention time for the boxed products by maintaining both the air freezing temperature and air speed with a horizontal throughout all levels. A box freezer reduces workload and time, resulting in a reduction in labor costs.

Carton freezing systems simultaneously handle the various product sizes and types with different chilling and freezing needs.

Optimal Flexible, we can fully integrate with your in-line process to support a wide range of freezing and chilling applications. The system can handle products from your production room to the freezer, chiller, and palletizing area.

Unique Two Box freezer Models to satisfy all food plant needs

MRT (Multiple Retention Time) and VRT (Variable Retention Time) Tunnel Freezer with up to 3 unique freeze zones for products.

AAT freezers and chillers handle every type of packaging, including carton boxes, crates, trays and containers of any kind in bulk.

CUSTOM AAT BoxFreezer is available with 3 Independent freezing zones for products needing different freezing processes, and gentle handling.

MODULAR AAT Small Box Freezer is easily extended or relocated with very low assembly costs on-site as delivered in finished modules.

What are the benefits of the AAT BoxFreezer design?

1) Transverse Air Stream: The freezing blowers are arranged on the side of the freezer so that the air stream blows directly into the product stack. Chilling air reaches the product faster and shortens the freezing time. The total air path is shorter than in other systems because the air only has to cross the plant's width.

The result is that if the plant is 30 meters long and 6 meters wide, the system only has to chill 6 meters.

Thus offering a consistent temperature and more uniform freezing of the products.

2) New Advanced Multi temperature Up to 3 freezing zones can be programmed independently. For example, zone 1 is used for shock freezing to −20 °C, zone 2 for cooling, and zone 3 can be switched off, thus saving energy.

3) Flexible In and Output: The locks are customized to suit your existing plant layout, keeping transport paths as short as possible and minimizing space with a more flexible line design.

4) Accessibility Workers can enter the Box Freezer even while it runs because only the product zones are refrigerated. Apart from the flexibility of size, we can offer various choices as to the input and output of products.

Ready to Increase Production?

Call us, and an Advanced Freezer expert will help guide you to the next level.

"Schedule your FREE consultation today

and discover more about the AAT BoxFreezer.

Don't wait any longer!"