Multipass IQF Belt Tunnel Freezer manufacture by Advanced Freezers

Multipass IQF Belt Tunnel Freezers for Poultry, Red Meat and Seafood

Advanced Equipment is a Multipass IQF belt tunnel freezer manufacturer that freezes or chills products larger than 1/2 inch round without any surface moisture, such as Italian pasta, fried breaded, or battered products. Poultry, red meat, and seafood processing are the primary industries that utilize Multipass tunnel freezers.

Advanced Equipment is a globally recognized brand for spiral and tunnel freezers. We have been designing and manufacturing IQF freezers for over 30 years. Our spiral and tunnel systems are constructed in-house, guaranteeing complete quality control. We also build our own parts to our strict specifications, which reduces the cost of our tunnel freezers.

Multipass Freezer Applications

POULTRY INDUSTRY - chicken parts, chicken nuggets

RED MEAT INDUSTRY - meatballs

SEAFOOD INDUSTRY - fish sticks, raw shrimp, fish fillets

Why You Should Buy From the Advanced Equipment Inc. Freezer Factory

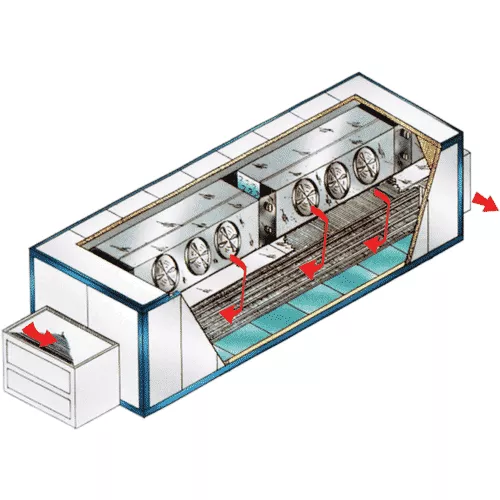

Multipass IQF Belt Tunnel Freezers Manufactured by Advanced are continuous in-line belt freezers designed to minimize product weight loss and assure quality and gentle handling during the freezing process.

Our unique horizontal airflow pattern minimizes Product shrinkage to as low as 0.15%. If your needs are unique, we also offer custom tunnel freezers.

Food products are evenly fed directly onto the loading freezer belt from the production line. The belt quickly transports the product into the low-temperature freezing zone. The product goes through the Multipass of belts before being discharged at the same or opposite end of the tunnel freezer.

Our tunnel freezers are factory-assembled and designed to minimize site installation time. Advanced tunnel freezers take up minimal space, reducing the cost of ownership. All our spiral and tunnel freezers are built to USDA, FDA, UL, CFIA, OSHA, and CSA Specifications and standards.

Our Tunnel Freezer Advantages

Many inherent advantages come with Advanced tunnel freezers. Here are a few advantages included with Advanced IQF freezers:

LOW OPERATION COSTS:

Our tunnel freezers offer lower operating costs than C02, nitrogen, and other freezers. This is achieved by utilizing the most efficient mechanical refrigeration method combined with our new unique, low-pressure, high-velocity, horizontal airflow recirculation system. The horizontal airflow ensures that heat is continuously scrubbed from all sides of the product while moving through the tunnel freezer.

LOW INVESTMENT:

Our Multipass tunnel freezer is the most economical IQF freezer in its class. Every component of our freezers is manufactured in our well-equipped engineering and manufacturing facility, which allows us to pass on the savings to our customers without sacrificing quality.

CUSTOM DESIGN:

Advanced Equipment begins with a standard design that is carefully customized to meet most standard needs. However, we also custom-design our Equipment to meet customer requirements.

ADVANCED SANITIZATION:

The Advanced CIP System Provides A Sanitary Design Of A High-Efficiency, Energy-Saving Cleaning Solution For Reduced Operating Costs, Ease Of Cleaning, And Trouble-Free Production.

Confused?

Shopping for tunnel freezers can be confusing. Call us, and an Advanced Equipment engineer will provide any information you need. You can also schedule a free, no-obligation consultation on our IQF Multipass tunnel freezers.