Clean-in-Place CIP Freezer Sanitation

Advanced Clean-In-Place CIP manufacturer and Sterilization-In-Place (SIP) systems provide automatic cleaning and disinfecting without major disassembly and reassembly work, saving plant downtime and significant labor costs.

With the automatic Advanced IQF freezer cleaning-in-place system (CIP), you press one button, and the system cleans itself and runs on timers through washing cycles like any modern washing machine.

CIP cleaning systems are highly beneficial for operations in which the interior surfaces of equipment, such as tanks and pipes, cannot be easily reached for cleaning.

As a Clean-in-Place CIP Manufacturer, we retrofit low-profile CIP systems for existing food plant freezer systems.

Every Clean-in-Place CIP retrofit upgrade is adapted to customer requirements and always leads to noticeable savings.

Individualized Custom Food plant freezer-specific configurations offer fast installation and short downtime. Complete integration into the existing process control system ensures automatic and trouble-free cleaning and higher economic efficiency at the same time.

Cleaning-in-Place CIP Manufacturer Simplicity in design

- Minimal hard-to-reach places and fewer crevices

- More open areas that are easy for system nozzles to spray

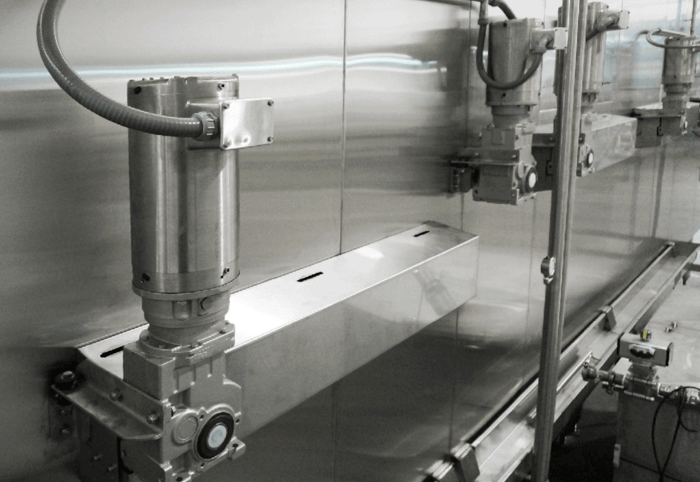

- Direct drive systems on spiral freezers, instead of unsanitary chain drives

- Drive systems mounted outside the product area to eliminate sources of contaminants

- All major belt structure supports are moved outside the product area

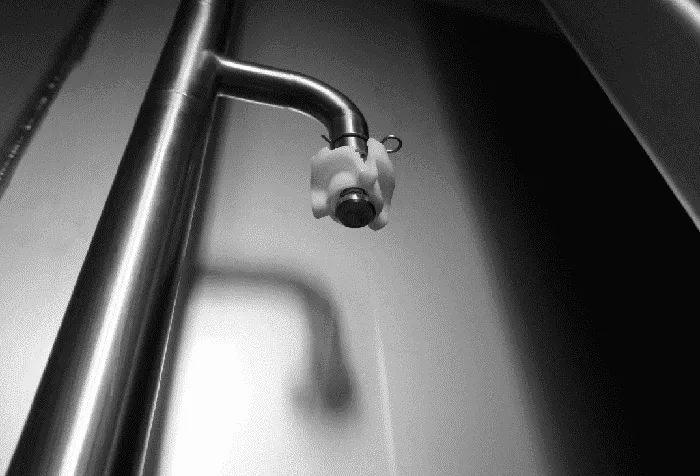

- Open-style CIP tank for easy cleaning and inspection

- The entire freezer floor is sloped to drain to the CIP collection tank

CIP Clean-In-Place SIMPLICITY in Cleaning

CLEANABLE MATERIALS

- Everything besides the aluminum fins on the coil,

The plastic belt, if equipped, is made of stainless steel or food-grade hygienic plastic. - Coils are built with aluminum or stainless-steel tubing with aluminum fins

- Optional plastic color-coded belts for easy identification to prevent contamination

- You need 304 stainless steels with 2B finishing, but you can also choose 316 stainless steels.

- Preference for smooth surface belts for easy cleaning

- The USDA and FDA approve all belts for use in food processing

EASE OF OPERATION

- Optional feature for steam sanitizing, with a steam distribution system

- All parts are rated for steam temperature

REDUNDANT CLEANING / COMPLETE COVERAGE

- More spray nozzles and overlapping coverage to eliminate dead zones

- The belt washing system cleans the entire belt and is a standard feature

- Coils are washed thoroughly from the side and the top

- Coils can be equipped with inline tubing, which has a continuous plate fin design deep throughout the row without any gaps for collecting debris or frost